Additive Manufacturing brings Optimus Primal into real world

August 17, 2023

Velo3D Inc, Campbell, California, USA, has partnered with Paramount Pictures and Joel Telling, @3DPrintingNerd on YouTube, to bring a Transformer into the real world with metal Additive Manufacturing. The result? A statue of Optimus Primal’s head with the strength of a rocket engine.

The finished Transformer head weighs 79 kg, with the stand adding a further 27 kg, and measures around 600 x 380 x 300 mm.

In the following video, Telling details the build process which took place over five and a half days within a large-format Sapphire XC Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machine at Velo3D. The material chosen was Inconel 718, a high-performance nickel-based alloy known for its strength as well as its heat and corrosion resistance. The build plate alone weighed 272 kg, in an effort to counterbalance any stresses encountered during the build process of the massive piece.

“[Inconel 718] has never been used for a project like this – you are witnessing a first of its kind,” Telling emphasised.

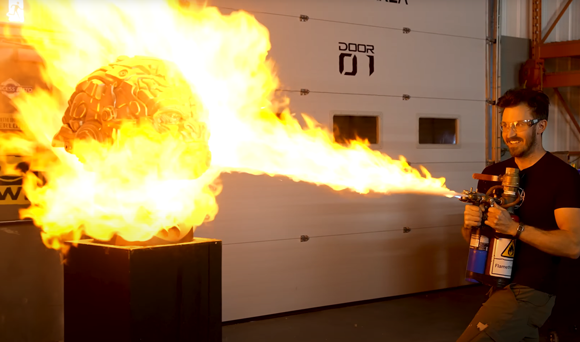

To highlight the strength of both Inconel 718 and the Additive Manufacturing process, Telling brought the piece for testing at the studio of James Hobson, CEO, of Hacksmith Industries (@thehacksmith). Optimus Primal underwent stresses from concrete blocks dropped from varying heights, impacts with metal rods which bent upon impact with the head, slicing efforts from a ‘plasma saber’ which reaches temperatures over 2204ºC, and the full force of a literal flamethrower – all without sustaining any harm.

Telling also visited the home of Tested (@tested), were he introduced Optimus Primal to Adam Savage’s 6.3 million YouTube subscribers. Here, he explained how Velo3D used their Sapphire XC to additively manufacture the ‘life-size’ sculpture, and how metal AM parts are being used in industries such as aerospace thanks to its unique capabilities.

The Velo3D Sapphire XC is capable of building parts 600 mm in diameter and 550 mm in height; it utilises eight 1 kW lasers for faster build time at scale. The risk of part collision is eliminated by a proprietary noncontact recoater, which both protects the build and the recoater while enabling thinner walls and more accurate builds. Consistent geometric accuracy, surface finish, and validated material properties are also ensured by standardised and controlled parameter sets, as well as automated calibrations.

Those interested in producing their own iteration of the Optimus Primal head – or a smaller full-body model – can do so from digital preparation files offered by Paramount Pictures at its official Printables account.