Additive manufactured permanent magnets from Oak Ridge said to outperform conventional versions

November 8, 2016

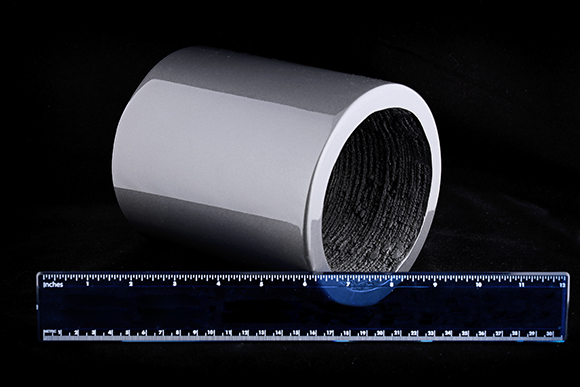

This isotropic, neodymium-iron-boron bonded permanent magnet was 3D-printed at DOE’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory

Researchers at the US Department of Energy’s (DOE) Oak Ridge National Laboratory, Tennessee, USA, have demonstrated that permanent magnets produced by Additive Manufacturing can outperform bonded magnets made using traditional techniques while conserving critical materials.

Scientists fabricated isotropic, near-net-shape, neodymium-iron-boron (NdFeB) bonded magnets at DOE’s Manufacturing Demonstration Facility at ORNL using a Big Area Additive Manufacturing (BAAM) machine. The result, published in Scientific Reports, was a product with comparable or better magnetic, mechanical and microstructural properties than bonded magnets made using traditional injection moulding with the same composition.

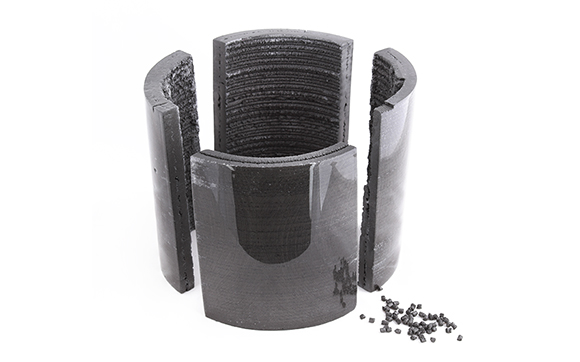

The Additive Manufacturing process began with composite pellets consisting of 65%vol isotropic NdFeB powder and 35% polyamide (Nylon-12) manufactured by Magnet Applications, Inc. The pellets were melted, compounded, and extruded layer-by-layer by BAAM into desired forms.

“While conventional sintered magnet manufacturing may result in material waste of as much as 30 to 50%, Additive Manufacturing will simply capture and reuse those materials with nearly zero waste,” stated Parans Paranthaman, principal investigator and a group leader in ORNL’s Chemical Sciences Division. The project was funded by DOE’s Critical Materials Institute (CMI).

Using a process that conserves material is especially important in the manufacture of permanent magnets made with neodymium, dysprosium – rare earth elements that are mined and separated outside the United States. NdFeB magnets are the most powerful on earth and used in everything from computer hard drives and head phones to clean energy technologies such as electric vehicles and wind turbines.

Composite pellets are melted, compounded, and extruded layer-by-layer into desired forms

“The printing process not only conserves materials but also produces complex shapes, requires no tooling and is faster than traditional injection methods, potentially resulting in a much more economic manufacturing process,” added Paranthaman.

“Manufacturing is changing rapidly, and a customer may need 50 different designs for the magnets they want to use,” stated ORNL researcher and co-author Ling Li. Traditional injection moulding would require the expense of creating a new mould and tooling for each, but with Additive Manufacturing the forms can be crafted simply and quickly using computer-assisted design, she explained.

Future work will explore the printing of anisotropic, or directional, bonded magnets, which are stronger than isotropic magnets that have no preferred magnetization direction. Researchers will also examine the effect of binder type, the loading fraction of magnetic powder, and processing temperature on the magnetic and mechanical properties of printed magnets.

Alex King, Director of the Critical Materials Institute, thinks that this research has tremendous potential. “The ability to print high-strength magnets in complex shapes is a game changer for the design of efficient electric motors and generators,” he said. “It removes many of the restrictions imposed by today’s manufacturing methods.”

“This work has demonstrated the potential of additive manufacturing to be applied to the fabrication of a wide range of magnetic materials and assemblies,” stated co-author John Ormerod. “Magnet Applications and many of our customers are excited to explore the commercial impact of this technology in the near future.”

Contributing to the project were Ling Li, Angelica Tirado, Orlando Rios, Brian Post, Vlastimil Kunc, R. R. Lowden, Edgar Lara-Curzio at ORNL, as well as researchers I. C. Nlebedim and Thomas Lograsso working with CMI at Ames Laboratory. Robert Fredette and John Ormerod from Magnet Applications Inc. (MAI) contributed to the project through an MDF technology collaboration. The DOE’s Advanced Manufacturing Office provides support for ORNL’s Manufacturing Demonstration Facility, a public-private partnership to engage industry with national labs.

The article is available to view on the Nature website at: http://www.nature.com/articles/srep36212.