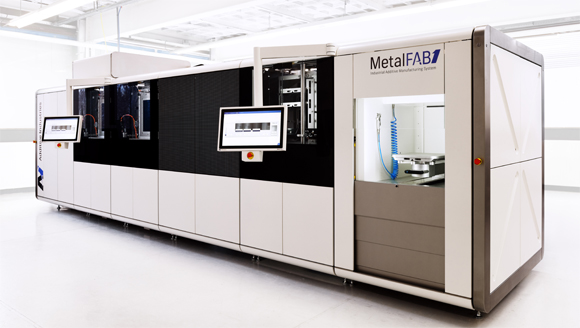

Additive Industries receives first MetalFAB1 follow-on order

May 19, 2017

Additive Industries, Eindhoven, the Netherlands, has received a follow-on order from Kaak Group for a MetalFAB1 system, which will be used to begin series production of industrial bakery system parts. The order, for a five-module four-laser production series system, comes within nine months of the installation of the first MetalFAB1.

In May 2017, Additive Industries upgraded their first MetalFAB1 system to the new four-laser version to increase its speed and capacity, but Kaak reports that it expects this will not yet be sufficient to keep up with the demand for internal parts for its baking systems. “Our engineers have embraced metal Additive Manufacturing and the number of parts with a positive business case over other fabrication technologies is growing rapidly,” stated Lodewijk van der Borg, Kaak Group CEO.

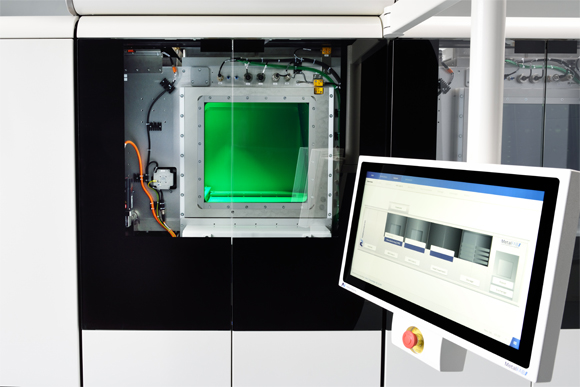

The build chamber on a MetalFAB1 machine (Courtesy Additive Industries)

Jaap Bulsink, Senior R&D Engineer at Kaak, added, “the MetalFAB1 has been used successfully to print a broad range of components for our systems, offering improved performance, lighter weight parts and a substantial reduction of development lead-time.”

According to Additive Industries, this follow-on order is a clear signal to the market that the MetalFAB1 system has matured and that the production series system – the first having been installed at BMW in December 2016 – is gaining traction. “We are proud and grateful for this follow-on order from Kaak, one of our most valuable Beta customers. They have truly stress-tested our MetalFAB1 system and helped us to improve its performance and mature the machine for series production. This order underlines their commitment and confidence in our technology,” stated Daan A J Kersten, CEO, Additive Industries.