ADDiTEC launches both robotic DED and multi-technology platforms for Additive Manufacturing

November 10, 2023

ADDiTEC, headquartered in Palm City, Florida, USA, has launched AMDroid, a laser-wire-based Directed Energy Deposition (DED) Additive Manufacturing robotic solution, and Hybrid3, a multi-technology manufacturing platform which combines Liquid Metal Jetting (LMJ) and laser-based DED capabilities with CNC machining.

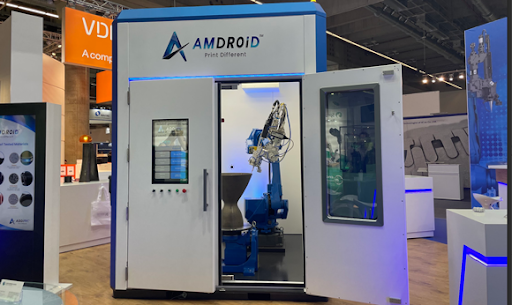

AMDroid

AMDroid is a turn-key deployable machine designed for a wide range of materials, including titanium. The machine is optimised to achieve a high deposition rate and is intended to make forward-deployable, on-demand manufacturing a reality, providing multi-axis and large-scale reactive and non-reactive Additive Manufacturing capability using a robotic architecture within a welded enclosure. AMDroid’s architecture enables simple installation and the commencement of manufacturing within a day.

ADDiTEC has collaborated with major industrial robot brands to provide flexibility in robot selection, enabling users to maximise Additive Manufacturing capabilities.

The AMDroid is expected to be available to ship in Q1/2024.

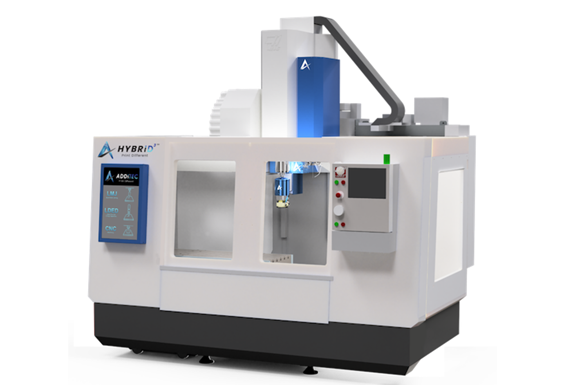

The Hybrid3

The Hybrid3’s multi-material capability integrates both LMJ and DED heads, alongside CNC machining, within a single machine. This enables the manufacture of complex components from a variety of materials.

LMJ, with its high-resolution capabilities, allows users to create intricate and finely detailed components. It utilises cost-effective welding wire, with complete material utilisation.

Laser-based DED is able to accelerate manufacturing, making it well suited to larger components and/or reduced lead times. DED also employs welding wire and complete material utilisation to drive cost efficiency.

The machine’s subtractive process, primarily driven by CNC machining, plays a pivotal role in achieving the desired surface finish and tight tolerances for parts manufactured using Additive Manufacturing processes.

Download Metal AM magazine