ADDiTEC acquires Elem Additive Solutions from Xerox to expand into liquid metal AM

August 15, 2023

ADDiTEC, headquartered in Palm City, Florida, USA, has announced the acquisition of Elem Additive Solutions from Xerox Holdings Corporation. The deal will see ADDiTEC expand its portfolio to include Elem Additive’s Liquid Metal Printing (LMP) technology, and is expected to open up new opportunities for growth and enhance its ability to serve the growing AM industry.

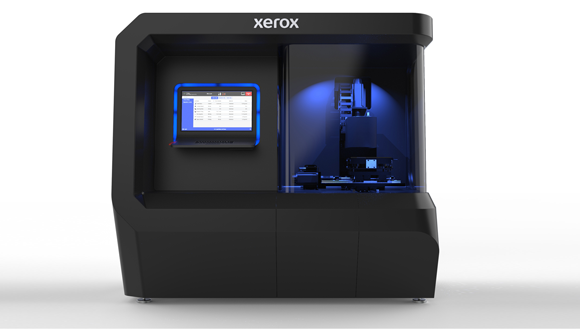

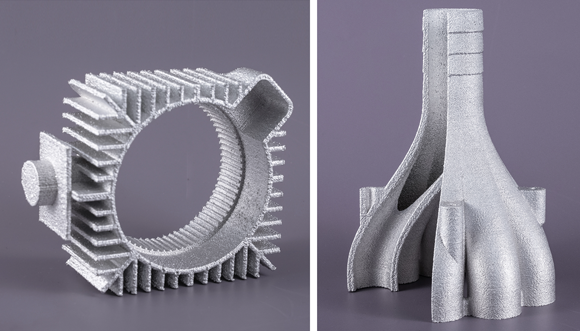

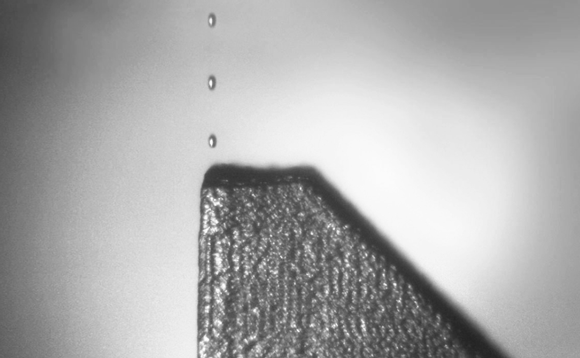

The LMP process falls broadly into the ISO/ASTM 52900:2015 category of Material Jetting, using widely available aluminium wire as the primary feedstock. The process then utilises magnetohydrodynamics to jet molten metal droplets at a specific rate and a specific mass. This method of Additive Manufacturing was developed by Vader Systems, which was acquired by Xerox in 2019. Since the acquisition, Xerox has matured the technology, leveraging its strong ink jetting expertise to refine the process.

“The Elem Additive team has seen tremendous success since the organisation was stood up nearly four years ago,” stated Steve Bandrowczak, Chief Executive Officer at Xerox. “In evaluating partners for this sale, it was critical we found a company with a shared mission that would sustain and advance Elem Additive’s innovation into the future. We are confident that ADDiTEC is the right partner and look forward to witnessing both teams’ shared success on the road ahead.”

Brian Matthews, founder and chief executive officer at ADDiTEC, added, “We’re very excited to have completed the acquisition of Elem Additive Solutions. This acquisition is a significant step for our company, we see incredible value in liquid metal print technology, and Elem Additive’s success supplements our growth efforts as we continue to develop new offerings and bring to market our turnkey metal Additive Manufacturing systems. We are delighted to have acquired Elem Additive Solutions and will strive to create further innovative services and solutions for our customers with the addition of this exciting liquid metal printing technology.”

In early 2021, Xerox unveiled and officially announced a strategic collaboration with the Naval Postgraduate School, installing its first ElemX machine at the school. A year later, in a first-of-its-kind installation, the ElemX was installed on a US Navy ship. Additional Elem Additive customers include Siemens, the US Department of Energy’s Oak Ridge National Laboratory, Rochester Institute of Technology, and Vertex Manufacturing. ADDiTEC stated it will continue to support these customers as the Xerox Elem Additive team transitions to the organisation.

Discover more:

Want more information on Xerox’s Liquid Metal Printing technology? Metal AM published a deep dive into the technology in the Summer 2022 issue. ‘What Xerox’s aluminium liquid metal AM offers for supply chain resiliency’ is available to read here, in full.

Download Metal AM magazine