ADDere demonstrates the benefits of Laser Wire Additive Manufacturing for large-scale parts

January 9, 2020

ADDere, the metal Additive Manufacturing division of Midwest Engineered Systems Inc. , headquartered in Waukesha, Wisconsin, USA, has reported the advantages of using Laser Wire Additive Manufacturing (LWAM) for producing large-scale, large-mass components for industries such as energy, aerospace, marine and defence.

“Currently, the AM focus has been on powder-based metal systems,” stated Scott Woida, ADDere President. “That focus had a lot of potential markets stuck on the outside looking in, but those industries now see a legitimate 3D printing roadmap for their parts through what we’ve been doing with ADDere.”

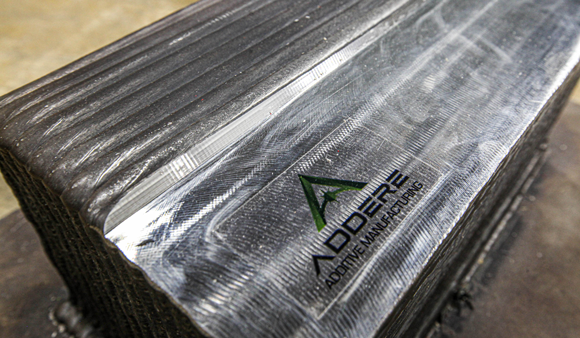

As an example of what’s now possible with wire based AM, ADDere has additively manufactured titanium and 17-4 stainless steel blocks. The titanium blocks are 15 cm x 15 cm x 30 cm and weigh 32 kg. The 17-4 blocks (also known as SAE type 630 or UNS 17400) are of the same dimension but weigh in at 55 kg. According to ADDere, the production of each of these blocks took just over six hours.

ADDere explains that, at over three times the size of most powder metal-based systems on the market, the standard ADDere AM systems feature a build area of 2 m x 1 m x 1 m and 2,000 kg capacity. The ADDere Laser Wire Additive Manufacturing system is said to specialise in producing additively manufactured large scale, near-net-shape parts in a variety of metals including titanium, stainless steel, Inconel and other superalloys, as well as most ferrous-based metals.

“We’ve already proven we can build things at large scales, these blocks show we can 3D print parts with substantial mass in a relatively competitive timeframe with casting,” commented Pete Gratschmayr, VP of Sales & Marketing. “Now real conversations can be had about printing large, high mass components like transmission cases, truck frames and turbine engine mounts without adding ‘in the future’ to the sentence. We can do it today.”