6K Additive awarded five-Year metal powder purchase agreement with US Army

September 26, 2023

6K Additive, a division of 6K Inc. headquartered in Andover, Massachusetts, USA, has been awarded a five-year Blanket Purchase Agreement (BPA) from the Army Contracting Command. This BPA is said to support the US Army Development Command (DEVCOM) in their strategic high-performance metal powders initiatives. The award was obtained through a competitive source selection process.

This BPA enables increased research and development efforts for weapons at DEVCOM, as well as meeting the additional demand for manufacturing prototypes and small quantities for Low-Rate Initial Production (LRIP). The BPA can be utilised by entities at various locations, including Picatinny Arsenal in New Jersey, Benet Labs in New York, Adelphi Laboratories in Maryland, and Rock Island Arsenal in Illinois.

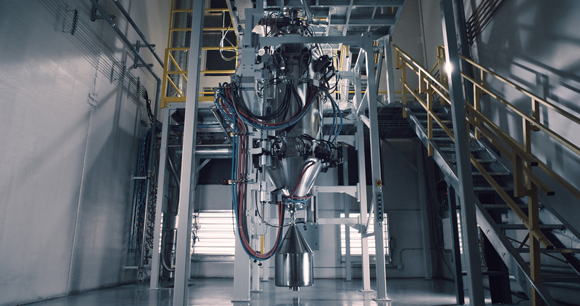

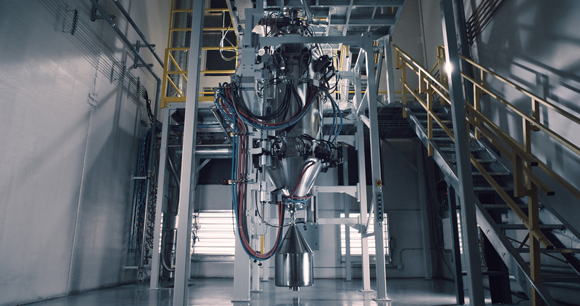

To produce the metal powders, 6K Additive will utilise their proprietary UniMelt microwave plasma platform. This technology allows 6K to source, process, and reclaim scrap components, shop scrap, and used powders, converting them into aerospace-grade metal powders.

Lieutenant Colonel Peter J Stambersky, USA Retired and Director of Federal Affairs at 6K, shared, “My experience from my service in the Army provides me with a unique perspective of the agreement. Clearly, there is a benefit to 6K Additive, but, more importantly, this agreement provides the US Army DEVCOM with access to critical materials for Additive Manufacturing derived from feedstock right here in the US. This agreement further establishes 6K Additive as a trusted partner for powder and as a source for reprocessing retired components from military aircraft and vehicles delivering a closed-loop, secure material supply to the US Army.”

The 6K UniMelt plasma production system is capable of converting various forms of high-value metal scrap into high-performance metal powders. These powders are used in Additive Manufacturing, Metal Injection Moulding, and other Powder Metallurgy production techniques. This system provides access to domestically sourced strategic metals and alloys like nickel and titanium, as well as refractory powders like C103 and tungsten, which are crucial for modern military missions.

The patented 6K Additive process cleans, prepares, and spheroidises scrap alloys, producing high-quality powders that are said to outperform atomisation technologies. This process ensures a secure and traceable domestic supply of critical materials for the US military, while eliminating performance issues that may arise from questionable foreign sourcing.

Download Metal AM magazine