6K Additive and Agile Space Industries partner to advance lunar mission with Ni625 powder certification

August 30, 2023

6K Additive, a division of 6K Inc. headquartered in Andover, Massachusetts, USA, and Agile Space Industries, a space propulsion technology company headquartered in Durango, Colorado, USA, have announced that Agile is seeking certification of Ni625 powder produced by 6K Additive for use in customer space applications, including critical rocket components.

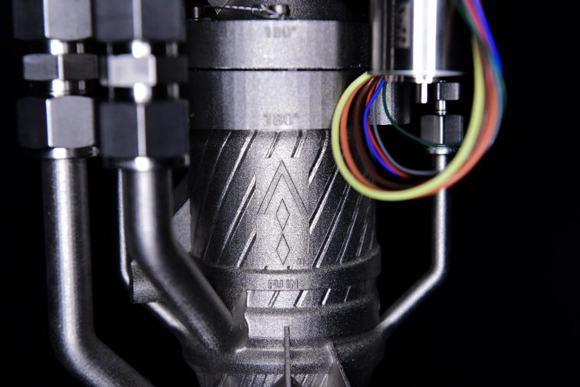

6K Additive’s Ni625 powder is currently undergoing certification for use at Agile’s manufacturing facility. The first parts to be produced using this powder will be used in Agile’s A2200 bipropellant hypergolic engine. The engines are powered by a pressure-fed hypergolic biorepellant, which does not require ignition as the hydrazine derivative fuel, M20, and MON3 oxidizer combust on contact. By leveraging Additive Manufacturing, the engine was designed to weigh only 5.9kg, while still producing 500-lbf of thrust, highlighting the benefits of lightweighting using AM technology, without compromising on power.

Kyle Metsger, Director of Additive Technology at Agile, explained, “By weight, 85% of our engine components are Additively Manufactured, meaning we rely heavily on AM powders that can withstand the extreme temperatures and forces generated during take-off and flight. 6K Additive allows us to additively manufacture using high-quality powders that are required for our critical applications, while also helping us meet our environmental goals through their recycling program and sustainably manufactured powders. 6K Additive can deliver extremely consistent powder that allows our production line to run the long build times required for these complex components.”

Traditional development cycles for aerospace components can take more than two decades. However, by harnessing the speed and flexibility of AM, Agile can compress development time to just 12 months. “A year-long development cycle still sounds like a very long time in many industries, but we are showing the primes in the aerospace industry what the future looks like. Moving to the larger TruPrint 5000 machine gave us the ability to qualify the new parameters for the machine and material simultaneously. In this way, AM allows us to be ‘Agile’ in name and practice,” continued Kyle Metsger.

Agile’s A2200 engines will power a Lunar lander vehicle. Developed for high-performance on demanding missions, the A2200 engine provides a specific impulse of over 318 seconds. Its integral pintle sleeve throttling mechanism allows for deep throttling, ensuring precise control and a smooth ride for a range of missions. The engine can adjust thrust from 50 to 100% in under 650 milliseconds, making it ideal for the demanding manoeuvring sequences required for lunar missions.

Frank Roberts, President at 6K Additive, commented, “We are always excited to partner with customers like Agile who leverage our high-quality powders to produce critical rocket parts to land on the moon. The fact that we can enable space exploration while continuing to lead the way with sustainability at home on Earth is the best of both worlds. Agile has a cradle-to-grave mentality around its products, and having 6K Additive supply the company with high-quality, sustainably produced Ni625 and provide an established waste stream to help with its environmental stewardship speaks to our mission of going beyond expectations for our customers.”

Download Metal AM magazine