3YOURMIND releases revised version of Additive Manufacturing Part Identifier

October 24, 2018

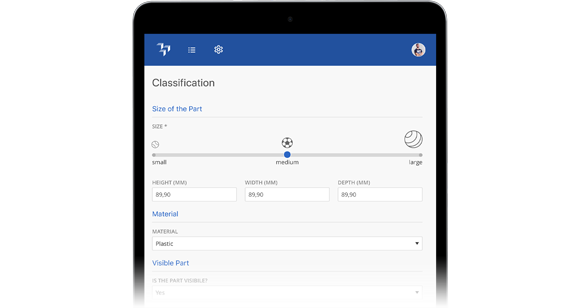

3YOURMIND’s revised AMPI tool automatically checks large part databases to detect components suitable for conversion to AM (Courtesy 3YOURMIND)

3YOURMIND, Berlin, Germany, has released what it describes as a completely revised version of its Additive Manufacturing Part Identifier (AMPI). This tool automatically checks part databases to detect which components could be good businesses cases for Additive Manufacturing, or for switching from traditional to Additive Manufacturing.

The analysis performed by the tool consists of both technical and economic aspects, and is based on metadata of individual components, such as material selection, quality and production requirements or, optionally, specifications from CAD programs. 3YOURMIND believes the AM Part Identifier could make it easier for companies to enter into Additive Manufacturing, and helps to reduce the time and cost involved in identifying suitable components for AM adoption.

Stephan Kühr, 3YOURMIND’s CEO, stated, “Working closely with customers, we added two new ways to find AM suitable parts: first, it’s now possible for any employee to suggest items for AM by feeding them directly into AMPI. Second, by enabling newly arriving print orders to be screened prior to being placed, companies can ensure the items are a definite fit for AM before moving into production.

One of the new features of the revised AM Part Identifier is its Use Case Screening function. According to 3YOURMIND, every employee in a company – whether involved in design, procurement or production – can now check the economical and technical feasibility of components for AM using a clearly structured and digitised process.

Dominik Lindenberger, AM Part Identifier Product Manager, 3YOURMIND, stated, “The value the new Use Case Screening offers directly affects employees’ workflow. Designers, for example, can run new parts through our screening process and check whether they are potential AM parts before they even open a CAD program.”

“They can then create an AM optimised design, avoiding costly redesigning of parts. And this is just one example of how departments can benefit from Use Case Screening,” he continued. “With the new version of the AM Part Identifier, we’ve stripped back the preparatory work and the expertise needed during the whole process of part identification for AM to make it even faster and even usable by average employees.”

Following Use Case Screening on potential AM parts and assemblies, relevant 3D models can be transferred into 3YOURMIND’s other tools for an end-to-end AM workflow. The full suite of tools included in the company’s Enterprise platform includes fully-automated printability analysis, component optimisation, material selection and price calculation, the placement of print jobs in the production workflow, and comprehensive data analysis for optimising AM.

3YOURMIND’s software solutions also include the On-Demand Production network, where customers can access external AM capacities from selected service providers around the world for the production of the identified components. This could further enable companies to enter the field of AM with a reduced investment in new machines and additional technical infrastructure.