3YOURMIND adds new features to AM Part Identifier software

October 19, 2019

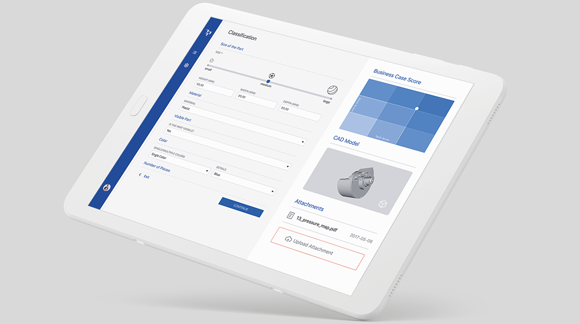

3YOURMIND, Berlin Germany, has added two new features to its AM Part Identifier (AMPI) software: Custom Reports and Technology Recommendations, in order to improve the output of results. The APMI automatically checks part databases to detect components which offer good businesses cases for Additive Manufacturing.

The new Custom Reports feature provides much finer data sorting to target the algorithms on specific business case applications, while the new Technology Recommendations feature uses pre-set algorithms to analyse AM use cases for specific technology applications.

The company states that its APMI software, which launched in 2017, is unique in that it doesn’t only evaluate the technical geometry of the 3D file, but also evaluates the surrounding business case for transitioning a part to Additive Manufacturing. The recent AMPI software release was designed to add nuance to the analysis of parts by filtering them into reports specific to particular materials, technologies and applications.

According to 3YOURMIND, the new developments were influenced by recent work with Bosch Industrial Additive Manufacturing and Gefertec GmbH, Berlin. The release also provides key improvements to increase the accuracy and usability of the AMPI.

Marcus Ortloff, Sales Engineer, Gefertec GmbH, commented, “We worked with 3YOURMIND to add algorithms for the WAAM technology into AM Part Identifier software. The process was clear and allowed us to quickly evaluate parts that are suitable for production with a high degree of accuracy.”

“We use Use Case Screening to help spread our own 3D printing technology throughout the larger Bosch organisation and to external potential customers,” stated Victor Roman, CEO of Bosch Industrial Additive Manufacturing from grow platform GmbH, a Bosch Company. “Prospects can upload parts and we can communicate directly about if parts are a good fit for our technology.”

“That helps to lower the barrier to using Bosch Industrial Additive Manufacturing and allows us to open a dialogue directly with potential new users,” he explained. “Without a digital interface, it would be much more difficult to spread our innovation.”