3T RPD expands metal Additive Manufacturing capacity

December 8, 2016

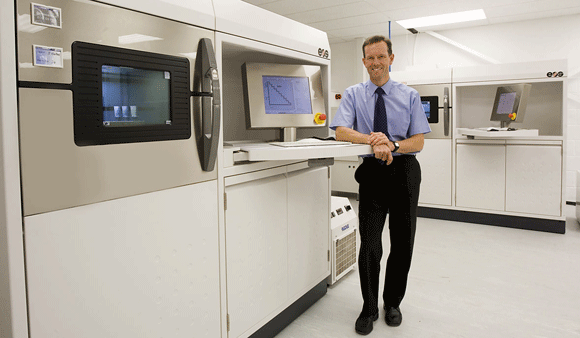

3T RPD has a suite of 13 metal AM machines manufacturing parts for its customers around the world

3T RPD, one of the UK’s largest Additive Manufacturing service providers, has opened a new metal Additive Manufacturing production facility near its current site in Newbury, Berkshire. The move follows recent investments in new AM machines and paves the way for further expansion of its metals and plastics AM production capacity in 2017. The company stated that the new facility triples its space for metal AM production and has given 3T RPD the chance to expand its finishing capability, bringing the whole metal AM production process in-house and creating a one-stop service for its customers around the world.

3T RPD’s new site is already manufacturing metal AM parts and in addition to the current complement of AM machines it will shortly include an automated finishing machine, a laser marking machine, NDT, multi-axis CNC and a large vacuum furnace. The size of the site allows 3T RPD to continue to install more AM machines as demand for AM production ramps up.

“This expansion has three aims, firstly to increase our production capability, secondly to increase the consistency of our production output, and thirdly to provide our customers an AM service covering the complete process chain,” stated Ian Halliday, CEO of 3T RPD. “As the demand for AM production builds, 3T RPD is determined to grow to meet customers’ AM production requirements and to be their first choice for production metals and plastics AM. This expansion is part of a programme of investment and is the first of many planned AM production developments from 3T RPD.”