3DEO and Azoth receive design excellence awards for metal Additive Manufacturing

July 7, 2023

The 2023 Powder Metallurgy Design Excellence Awards, sponsored by the Metal Powder Industries Federation (MPIF), were announced during the co-located International Conference on Powder Metallurgy and Particulate Materials (PowderMet2023) and Additive Manufacturing with Powder Metallurgy (AMPM2023) held in Las Vegas, Nevada, USA, June 18-21.

This year, the MPIF awarded ten Grand Prizes and fifteen Awards of Distinction to winners across three categories: Conventional Press and Sinter PM, Metal Additive Manufacturing, and Metal Injection Moulding.

In the Metal Additive Manufacturing category there were three winners in total, two receiving a Grand Prize and one an Award of Distinction.

Grand Prizes

Motors/Controls & Hydraulics

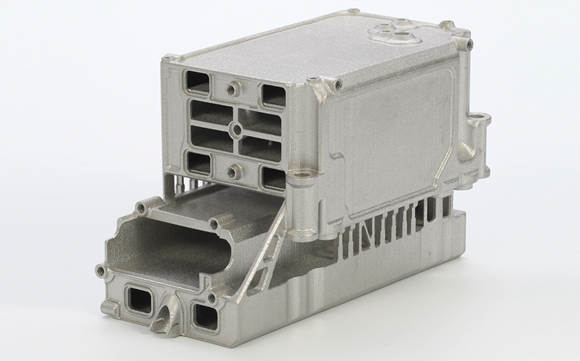

A Grand Prize in the Industrial Motors/Controls & Hydraulics Category for Metal AM components was awarded to Azoth, based in Ann Arbor, Michigan, USA, for a fluid matter exchanger. Despite its relatively simple exterior, the part’s interior is extremely complex.

The part is processed via Binder Jetting Additive Manufacturing, using 316L stainless steel powder with the as-built part about 20% larger to account for shrinkage during sintering. The customer for whom the part was built performs flowability as well as pressurised leak testing of the parts.

The hollowness, internal channels, internal filters, and other complex features of this fluid matter exchanger make it a part only viable through Additive Manufacturing.

Medical/Dental

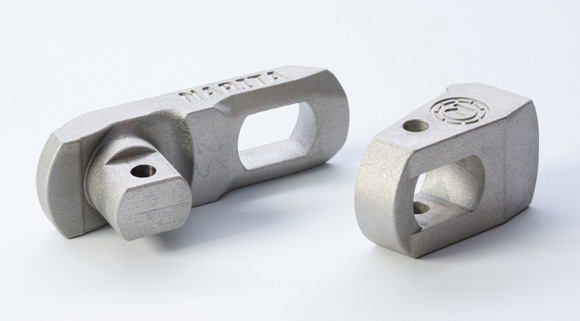

In the Medical/Dental Category for Metal AM components, a Grand Prize was awarded to 3DEO, Los Angeles, California, and its customer USB Medical, Hatboro, Pennsylvania, for a surgical implement articulation joint and pivot. The assembly is part of a surgical implement for performing laparoscopic heart surgery. The instrument is used to lift the heart gently, granting the surgeon access to the back of the heart.

The three-part assembly is built from 17-4 PH stainless steel using 3DEO’s proprietary Additive Manufacturing process, in which 100 μm layers of powder are deposited, uniformly bonded edge-to-edge, and machined on a per-layer basis until the parts are fully built.

For this part, demand volume did not warrant MIM tooling investment, and metal AM retained the customer’s ability to make future design changes.

Award of Distinction

Hardware/Appliances

In the Hardware/Appliances Category for Metal AM Components, an Award of Distinction was given to 3DEO and its customer Narita Manufacturing, Belvidere, Illinois, for a fastener assembly. The fastener attaches the inter-car baffles to retaining frames on bullet trains.

The 17-4 PH stainless steel metal AM assembly replaced ten individual components and four rivets, eliminating riveting, welding, and grinding from the production process. The parts must be able to be rotated with a tool but remain tamper resistant to passengers and resist unintended rotation due to train car motion and vibration.

Download Metal AM magazine