3D Systems announces new bespoke solution for maxillofacial surgeries

April 29, 2021

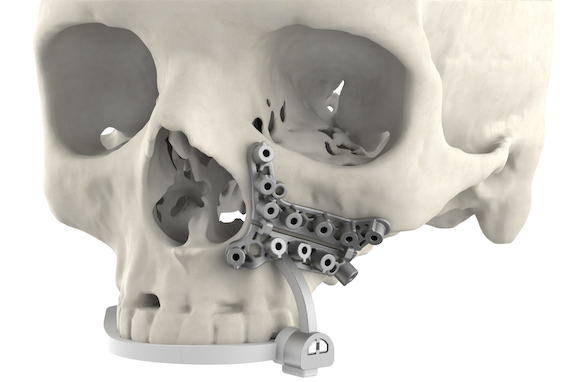

3D Systems, Rock Hill, South Carolina, USA has announced VSP® Hybrid Guides – the latest enhancement to its VSP surgical planning solutions portfolio. This solution for maxillofacial surgeons combines the strength of titanium with the relative softness of nylon in a single, patient-specific guide with registration to the dentition for added confidence in guide placement and surgical site visibility.

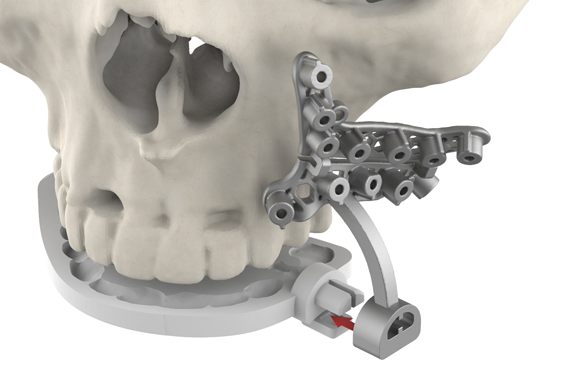

VSP Hybrid Guides capitalise on the benefits of each material: tooth-based registration is achievable with nylon material, and the profile advantages of a rigid metallic cutting and drilling guide are preserved. The new guides are assembled with easy-to-use connection sites that are engineered to confirm a proper connection. Depending on the surgeon’s preference, patient-specific instruments can be designed that allow multiple cutting/drilling locations on a single occlusal-based guide.

A secondary benefit of using occlusal registration is the potential for a reduced guide footprint. The slimmer profile guides not only provide easier placement in areas with limited exposure, but improve a surgeon’s visibility of the surgical site.

“3D Systems and its VSP surgical planning and guides are an integral part of my ability to deliver highly successful outcomes for my patients undergoing corrective jaw surgery,” stated Dr Jay Neugarten, New York Center for Orthognathics and Maxillofacial Surgery. “The new VSP Hybrid Guides are the next generation of occlusal-based surgical guides. To be able to combine two materials – nylon and titanium – to create cutting and predictive hole-drilling surgical guides that register to the dentition enables a precise and accurate surgical outcome for my patients. Using the VSP Hybrid Guides together with Stryker’s Facial iD customised plates streamlines my workflow in surgery.”

The innovative surgical guides developed as part of this new solution are manufactured using 3D Systems’ LaserForm Ti and DuraForm® ProX PA materials on the DMP Flex 350 and ProX® SLS 6100 production-grade Additive Manufacturing systems. Creating patient-specific surgical guides as part of the VSP System has been shown to save surgeons and patients hours in the operating room.

“3D Systems prides itself on our customer-centric innovation, and our ability to deliver patient-specific solutions that change the way healthcare is delivered,” commented Menno Ellis, executive vice president, healthcare solutions, 3D Systems. “With the introduction of VSP Hybrid Guides, we’ve elevated the capability of our renowned VSP surgical solutions portfolio to facilitate craniomaxillofacial procedures. In partnership with our expert biomedical engineers, surgeons can develop effective surgical plans and patient-specific devices that help improve patient outcomes.”

3D Systems’ VSP technology received FDA market clearance as a service-based approach to personalised surgery, combining knowledge in medical imaging, surgical simulation, and AM. The surgeon initiates the process, bringing their clinical knowledge and desired surgical plan to an online web meeting with a 3D Systems biomedical engineer to simulate and plan the surgical procedure. The outcome is a digital plan that is transferred to the operating room via accurate additively manufactured, patient-specific models, guides, and templates. 3D Systems has provided VSP solutions or anatomical services in more than 140,000 unique patient cases.

VSP Hybrid Guides are the latest delivery on the shared vision and partnership of 3D Systems and Stryker to provide innovative solutions to the maxillofacial surgeon. The new hybrid guides are compatible with Facial iD®, Stryker’s portfolio of patient-specific plating solutions. The combined surgical planning, improved patient-specific guides, and patient-specific implant system offers the maxillofacial surgeon a complete end-to-end solution for a simplified patient-specific treatment experience. This offering is currently in a limited launch phase, with general availability intended for May 2021.

“It’s like using a satellite navigation system compared to a paper map,” added Neugarten. “This ability to seamlessly transfer my digital treatment plans to the surgical arena allows me to provide the highest level of care for my patients.”