Sciaky achieves record December with sale of four EBAM systems

January 5, 2018

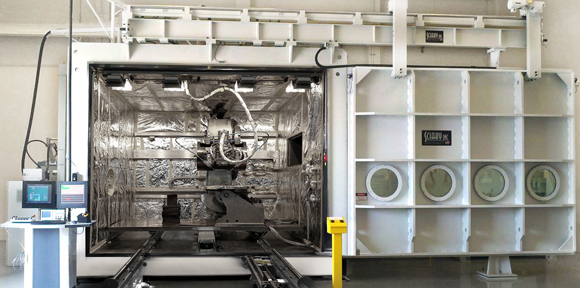

Among the four EBAM machines Sciaky sold in December was one EBAM 150 machine, which has a nominal part envelope of 3708 mm x 1575 mm x 1575 mm (Courtesy Sciaky, Inc.)

Sciaky, Inc., Chicago, Illinois, USA, a subsidiary of Phillips Service Industries, Inc. (PSI), posted record machine sales in the month of December with the sale of four Electron Beam Additive Manufacturing (EBAM®) systems.

According to the company, the machines were purchased for the production of titanium structures for aerospace applications, as well as large parts for ground-based military vehicles and warships.

Three EBAM 110 machines and one EBAM 150 machine were sold, the latter of which has a nominal part envelope of 3708 mm x 1575 mm x 1575 mm (146 in x 62 in x 62 in), making it possible to additively manufacture large metal parts in-house. All four systems will be delivered around mid-2018.

Scott Phillips, President & CEO of Sciaky, Inc., stated, “Sciaky is proud to deliver more best-in-class EBAM metal 3D printing systems to the marketplace, which will be leveraged in a wide range of land, sea, air and space applications. Now, more than ever, manufacturers are looking for ways to reduce time and cost associated with producing large, high-value parts, and Sciaky EBAM systems have a proven track record of helping manufacturers achieve these business-critical goals.”

Bob Phillips, Sciaky’s Vice President of Marketing, added, “January is shaping up to be another great month for EBAM machine sales, and there will be more exciting industry news coming from Sciaky in the near future.”

Sciaky reports that, in terms of work envelope, its EBAM systems are the most widely scalable metal AM systems in the industry. The company’s machines can produce parts ranging from 203 mm (8 in) to 5.79 m (19 ft) long at gross deposition rates from 3.18 – 9.07 kg (7-20 lbs) per hour.