Zeiss to integrate in-process monitoring in EOS AM machines

November 10, 2021

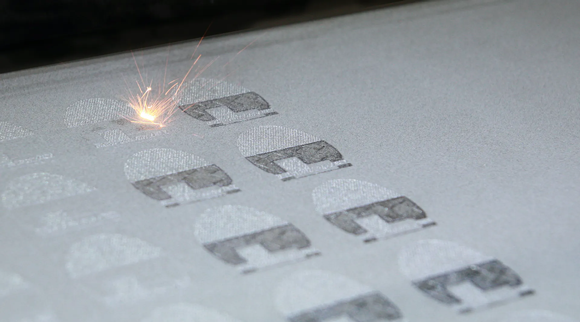

The Zeiss Group, headquartered in Oberkochen, Germany, and EOS GmbH, Krailling, Germany, have announced plans to jointly integrate and market the Zeiss AM in-process monitoring system for surveillance of powder beds in metal Additive Manufacturing.

A uniformly distributed powder bed is said to be essential for a stable and reliable AM process. Patented Zeiss technology is used to capture the height information of the powder bed, enabling the detection of grooves and elevations with a high degree of certainty. The acquired 3D information is analysed by a neural network, automatically notifying the user of irregularities in the powder bed.

The cooperation aims to integrate the Zeiss AM in-process monitoring into the EOS Laser Beam Powder Bed Fusion (PBF-LB) machines, giving users the ability to assess the powder bed during the build process as well as afterwards, with the option to intervene manually or automatically according to preference.

“We are confident that ZEISS can contribute with this product to help further industrialise Additive Manufacturing and that with EOS we found a strong partner for a successful market entry” stated Heiko Degen, Business Development Manager Additive Manufacturing Process & Control at Zeiss.

Dominik Hawelka, Product Line Manager at EOS, added, “The automated analysis of the powder bed quality and quick reaction to identify defects opens immense potential for cost savings. We are, therefore, developing an interface for our EOS M 290 that enables the communication of a Zeiss solution on our 3D printing system. As an example, information from the Zeiss product can be used to correct detected powder bed defects by triggering a second recoat step.”

Both companies will present further details of the collaboration at Formnext.