Xi’an Sailong produces its first tantalum surgical implant by Selective Electron Beam Melting

May 25, 2018

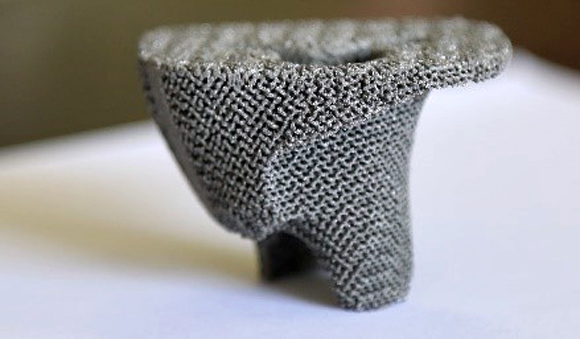

The custom, lattice-structured tantalum knee support component was produced for a knee revision surgery on an 83 year old patient (Courtesy Xi’an Sailong)

Xi’an Sailong Metal Materials Co., Ltd., based in Xi’an, China, has recently designed and manufactured a custom, lattice-structured tantalum knee support component for a revision surgery on an eighty-three year old female patient. The production of this implant comes after the company first reported its success in the Additive Manufacturing of tantalum components using its Selective Electron Beam Melting (SEBM) system in February, 2018.

Porous tantalum offers highly desired biocompatibility for use in surgical implants. However, it can be challenging to additively manufacture intricate tantalum implants due to the material’s high melting point (2996ºC) and reactivity.

This first tantalum knee support was developed with support from the Ministry of Science and Technology of China under a major research programme titled ‘Custom-printed tantalum implants by Selective Electron Beam Melting and clinical applications,’ and manufactured using a Sailong Y150 SEBM system.

The project was led by Professor Liu Yang of Southwest Hospital and Professor Huiping Tang of Xi’an Sailong Metal Materials Co., Ltd. and State Key Laboratory of Porous Metal Materials, Northwest Institute for Nonferrous Metal Research, China. The surgery was completed in April 2018 and, according to Xi’an Sailong, a recent post-surgical review suggests that the surgery was successful and the patient is recovering well.