Vertex orders two further Sapphire XC machines from Velo3D

November 15, 2022

Velo3D, Campbell, California, USA, has announced that PrinterPrezz subsidiary Vertex Manufacturing, Cincinnati, Ohio, USA, has ordered two Sapphire XC Additive Manufacturing machines to complement its existing fleet and meet the demands of its customers. The large-format Sapphire machines are calibrated for Inconel 718 and GRCop-42, and will be able to additively manufacture parts up to 600 mm in diameter and 550 mm in height.

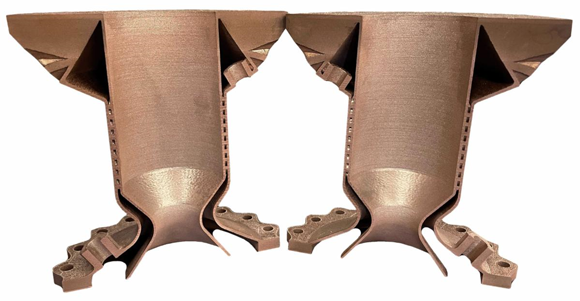

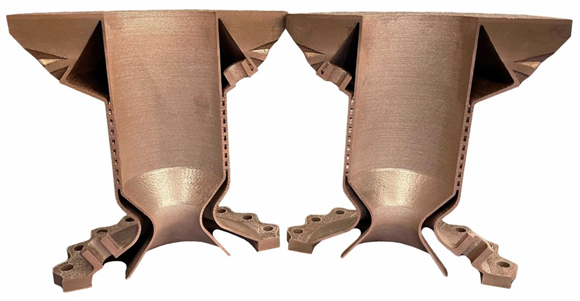

Vertex specialises in providing solutions to customer engineering challenges. The company also offers a range of post-processing services, including full five-axis machining and finished-product surface treatments. Vertex currently operates a fleet of Sapphire machines calibrated to additively manufacture in Inconel 718, a nickel-base superalloy that provides high strength and oxidation resistance even at near-melting point temperatures. Available at scale, Vertex also offers manufacturing using GRCop-42, a copper, chromium and niobium alloy that was developed by NASA for use in regeneratively cooled rocket engines.

“As the AM landscape continues to mature, the technology has become invaluable, enabling faster product development times and significantly reduced manufacturing cycles,” stated Tim Warden, VP of Sales and Manufacturing at Vertex Manufacturing. “Velo3D’s fully integrated solution allows our customers to print difficult geometries with limited support structures, so they can focus on optimising their parts rather than having to adjust and compromise designs. We’re thrilled to add these printers to our manufacturing floor, especially our new GRCop-42 printer, empowering our customers to solve their evolving demands.”

Dr Zach Murphree, Velo3D VP of Global Sales and Business Development, added, “The traction Additive Manufacturing continues to see in the aerospace industry is largely driven by the significant advancements that have been made and the ability for contract manufacturers like Vertex to execute successfully on its goal of delivering high-quality, finished parts, allowing engineers to focus on designing – rather than manufacturing. The feedback we’ve heard from Vertex’s customers has been very positive and it’s largely due to Vertex’s ability to deliver exactly what customers need.”

Those interested can learn more about Velo3D and Vertex’s partnership at Velo3D’s Hall 12.0, D01.