Velo3D produces twenty-one AM parts for Boom Supersonic jet

October 7, 2020

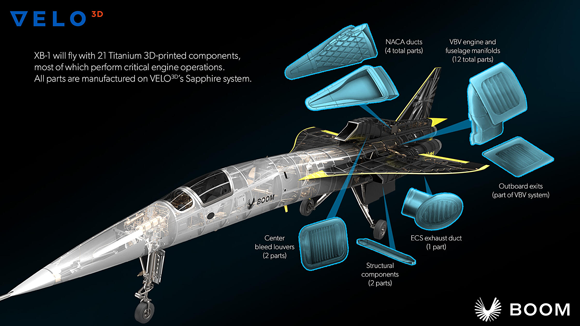

Velo3D, Campbell, California, USA, has produced twenty-one additively manufactured flight hardware components for aerospace company Boom Supersonic’s XB-1. The parts were produced on theVelo3D Sapphire metal Additive Manufacturing machine.

The XB-1 is said to mark a turning point in the commercial viability of supersonic travel, and demonstrates the power of Additive Manufacturing to enable innovation while accelerating product development.

Said to be the world’s first independently developed supersonic jet, the XB-1 will be used to demonstrate critical technologies for Overture, Boom’s future commercial airliner, such as advanced carbon-fibre composite construction, computer-optimised high-efficiency aerodynamics, and an efficient supersonic propulsion system.

Boom Supersonic and Velo3D announced a partnership in 2019 to manufacture complex flight hardware for the XB-1, and ran a series of qualification trials on Velo3D’s Sapphire metal Additive Manufacturing machine.

The additively manufactured titanium parts are used for engine hardware, the environmental control system, and structural components. Characteristics of the geometric designs include tall, thin walls with high aspect ratios, which are inherently difficult to manufacture with either traditional processes such as welding and casting, or even most existing Additive Manufacturing technologies.

“Aviation hardware is especially difficult to manufacture with 3D metal printing, due to challenging aerodynamic designs that must be balanced with superior durability and high-temperature requirements,” stated Benny Buller, CEO and founder of Velo3D.

Buller continued, “Velo3D’s technology allows the production of lightweight, complex designs for mission-critical applications in the toughest operating conditions. Our partnership with Boom is truly an advancement for the metal AM industry, and XB-1 supersonic aircraft is a game-changer for the aviation industry.”

Mike Jagemann, Head of XB-1 Production at Boom Supersonic, commented, “We strongly believe that supersonic is the future of flight and we’re appreciative of Velo3D in helping us to realise this goal with XB-1.”