Velo3D launches its first metal Additive Manufacturing system

August 20, 2018

Velo3D’s new Sapphire Additive Manufacturing system, designed for manufacturing components in high volumes (Courtesy Velo3D)

Velo3D, Campbell, California, USA, has launched its first metal Additive Manufacturing solution, comprised of the Sapphire™ Additive Manufacturing machine, Flow™ software, and Intelligent Fusion™ technology. The company states that the integrated offering could provide solutions for some of the most difficult AM challenges including product design limitations, part-to-part consistency, process control and cost-effective manufacturing.

Benny Buller, founder and CEO of Velo3D, stated, “Four years ago, we set out with the bold vision of creating technology that could manufacture parts with any geometry to take Additive Manufacturing mainstream.”

“Our approach relies on creating deep insights in physics fundamentals, enabled by research, characterising and understanding of core mechanisms, developing intelligent process control through software simulation and in-situ metrology,” he continued. “Today, Velo3D is working with some of the top OEMs and service bureaus creating parts that were once considered impossible.”

Sapphire system

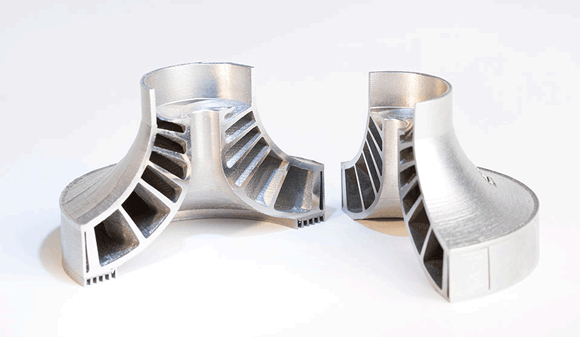

A shrouded impeller produced on the Sapphire system. The only support required on this part is the radial extrusion that supports the outer lip (Courtesy Velo3D)

The Sapphire Laser Powder Bed Fusion (LPBF) metal AM system is said to be designed from the ground up with high volume manufacturing in mind. It comprises a 315 mm diameter by 400 mm high build envelope, with dual 1 kW laser operation. To deliver superior part-to-part consistency, Velo3D reported that Sapphire’s integrated in-situ process metrology enables a closed loop melt pool control, which it says is the first of its kind.

The system is said to be capable of building complex geometries and allows designs with overhangs down to five degrees without supports, as well as large unsupported inner diameters of up to 40 mm. Minimum feature size and wall thickness is reported to be below 250 µm.

To maximise productivity, the Sapphire system comprises a module to enable automated change-over, enabling a new print to start without operator involvement within 15 minutes.

Flow build preparation software

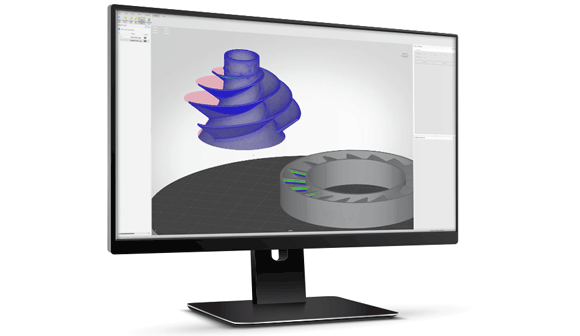

Velo3D’s Flow build preparation software (Courtesy Velo3D)

Velo3D’s Flow build preparation software is said to offer support generation, process selection, slicing and simulation of complex part designs to validate execution feasibility before the build. Deformation correction technology makes it possible to produce parts without the need for repeated iterations, reportedly achieving a first-build success rate of up to 90%.

The software also minimises the need for supports, reducing typical support volume by a stated 3-5 times, which removes or reduces the post processing necessary with conventional approaches.

Intelligent Fusion technology

The company’s Intelligent Fusion technology powers both the Flow software and Sapphire system, enabling an end to end integrated workflow. Intelligent Fusion is said to optimise the AM process by combining thermal process simulation, print prediction, and closed-loop control during build execution.