VBN Components receives award for its cemented carbide Vibenite alloy

June 29, 2020

VBN Components, Uppsala, Sweden, has received a “Best of Industry Award” in the category of Additive Manufacturing from Germany’s MM Maschinenmarkt, for its cemented carbide Vibenite® 480 alloy. The company received the award on June 25, during an online ceremony broadcast from Würzburg, Germany.

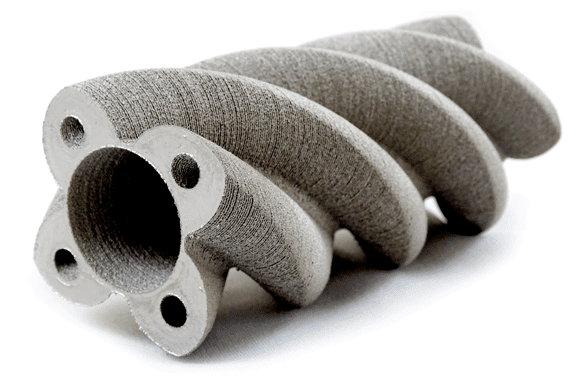

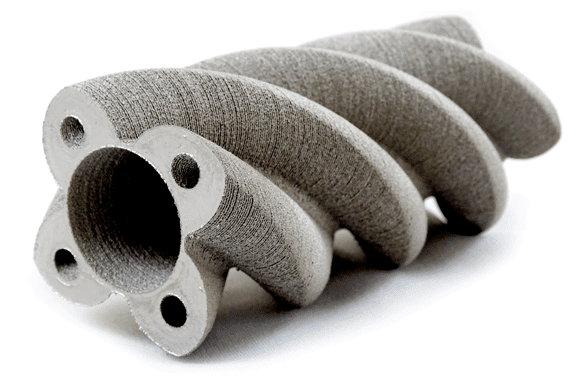

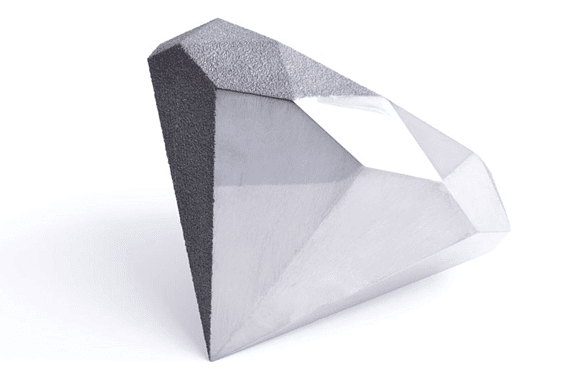

The company states that the patented Vibenite 480 alloy is extremely heat-resistant (up to at least 750°C) and wear-resistant and corrosion-resistant. Processing via Additive Manufacturing is enabling the production of complex shapes for industrial tools and components, and reducing environmental impact.

According to VBN Components, the Vibenite 480 is based on metal powder produced through large scale industrial gas atomisation, said to minimise both cost and environmental impact. The new material combines the toughness of Powder Metallurgy High-Speed steels (PM-HSS) with the heat resistance of cemented carbides, which is why this new group of materials is named as hybrid carbides.

Vibenite 480 has a carbide content of ~65% but is said to be tougher than regular cemented carbides and therefore suitable for more complex details. Typical applications for this material are cutting tools for milling, drilling and gear cutting, which require good wear resistance at high temperatures, combined with good toughness. The AM process opens up completely new possibilities in the design of the tools, states the company.

In addition, Vibenite 480 is also reportedly suitable for all components that are subject to high wear, such as pump components, nozzles, and baffle plates – said to be an ideal alternative to hard metals or wear-resistant alloys.

Due to Additive Manufacturing, the components can rapidly be produced in near-net-shape, with design options offering new approaches to make components more wear-resistant. Additively manufactured cutting tools or wear components can be manufactured with very short lead times, which opens up many new approaches to build, test and improve prototypes and finally take the optimised component or cutting tool to serial production.

“Germany is a very important market for us, and we are delighted to receive this award in this heavy competition,” commented Ulrik Beste, CTO of VBN Components. “The company vision is to renew the materials industry in the world by developing materials that offer uniqueness and improved industrial performance, and the Best of Industry Award is a great recognition to our achievement.”