Vader Systems announces new developments in its liquid metal AM technology

April 27, 2018

Vader Systems, Buffalo, New York, USA, announced three unique systems based on its patented Magnet-o-Jet™ technology at this week’s RAPID + TCT exhibition in Fort Worth, Texas, USA.

The company stated that these solutions have been designed to address the ever-evolving needs of the rapidly growing metal Additive Manufacturing market. The solutions include the Vader Polaris™ liquid metal AM system, The Magnet-o-Jet™ Subsystem for hybrid manufacturing equipment integration and the Ares™ Microsphere Production System. These, stated Vader Systems, offer customers greater flexibility to deploy the its liquid metal technology.

Vader works collaboratively with customers to understand their unique application needs and, it was stated, is therefore well positioned to create customised solutions. This intuitive approach delivers engineered solutions that are cost-effective while satisfying unique customer requirements that can be solved by the Vader technology platforms. Scott Vader, President of Vader Systems, stated, “Our new technology platforms emphasise Vader’s unique ability to be the agile additive solution for the market.”

The Polaris™ system

The Polaris™ is a turnkey system used to transform metal AM parts from conceptualisation to actualisation using Vader’s patented liquid metal process. Vader announced that it can now manufacture the most sought-after aluminium alloys on the market, including 6061 and 7075.

Producing parts at rapid speeds with low-cost material and virtually no waste creates high value for customers, the company stated, adding that it believes that these advantages are compounded when also considering the safety of using non-hazardous input materials, which stand in strong contrast to the substantial requirements that come with operating a metal powder-based AM machine.

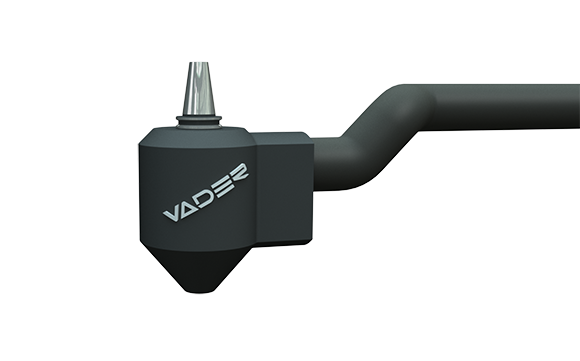

The Magnet-o-Jet™ Subsystem

The Magnet-o-Jet™ Subsystem is designed to integrate into hybrid manufacturing systems such as CNC and machine centre equipment. By eliminating the use of metal powders, the company claims that the Magnet-o-Jet™ system allows manufacturers to produce parts and precisely finish them all in one system.

Vader collaborates closely with customers to assure its Magnet-o-Jet™ subsystem is customised to work within existing or planned equipment and workflow. As with the Polaris™ System, the benefits are claimed to be significant, including isotropic material properties, enhanced safety and finished parts with full density.

The Ares™ Microsphere Production System

The Ares™ Microsphere Production System is reported to produce highly uniform and consistent metal microspheres for on-demand usage. The Vaderite™ microspheres, stated the company, have been tested by a leading national laboratory and show best-in-class results. Printing microspheres on demand eliminates the need to carry powder inventory and enables a wide variety of small batch applications. The microspheres are extremely consistent with a very narrow particle size distribution. These attributes allow for excellent flowability, nearly 100% material usage, and more reliable results.