VAC-U-MAX, GEMCO and VORTI-SIV announce powder recovery and reconditioning system

April 16, 2024

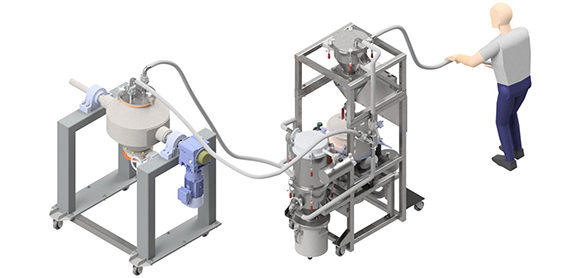

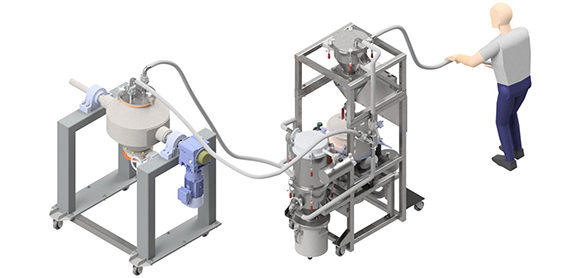

VAC-U-MAX, based in Belleville, New Jersey, USA, along with GEMCO, Middlesex, New Jersey, and VORTI-SIV, Salem, Ohio, have announced the collaborative development of the AM-MPRR, a portable system designed to manage the metal powders used in Additive Manufacturing. This system handles the entire lifecycle of metal powders for Laser Beam Powder Bed Fusion (PBF-LB) and Binder Jetting (BJT), including unloading, handling, reclamation, and reconditioning. AM-MPRR will be introduced on booths 1525 and 1531 at RAPID + tct 2024, scheduled to take place June 25-27 at the Los Angeles Convention Center, California.

The new system utilises advanced vacuum technology to fully extract metal powders from the build bed while removing unused metal powder and reconditioning it for future use. It is reputed to reclaim unused powders from the bed in 85% less time than traditional methods, reconditioning them for reuse.

Residual identical powder from multiple machines can be delivered to the tumble blender module to be homogenised into a consistent master batch for reuse. Another version of the MPRR blends the powder and also dries it to a single-digit moisture content to improve the powder flowability.

AM-MPRR integrates with GEMCO’s mixing and drying technology, allowing users to reclaim and recondition unused metal powders from the building process and extend their useful life. Overall, this system is intended to lead to waste reduction, material usage optimisation, and cost savings – all while maintaining the high-performance standards required for critical AM applications.

“Experience is not an experiment,” said Doan Pendleton, president of VAC-U-MAX. “There is no need to reinvent the proverbial wheel for metal powder handling needs. The MPRR family of products comes with experience as a standard feature, from a team of companies including GEMCO and VORTI-SIV that have supported Additive Manufacturing and 3D printing since its early days.”

All MPRR products are designed to process reactive and non-reactive metal powders in accordance with NFPA and UL standards in a plug-and-play design. VAC-U-MAX, GEMCO, and VORTI-SIV have also highlited the improved ergonomics for operators, safe material handling, and reduced spillage from manual handling of small powder containers or manual sieving.

Casey Bickhardt, GEMCO President/CEO/owner shared, “We are firmly committed to advancing the entire Additive Manufacturing industry. This new, joint AM-MPRR effort perfectly embodies that spirit.” This commitment is further exemplified by GEMCO’s recent membership of the National Institute of Standards and Technology’s (NIST) Metal Additive Manufacturing Powder Consortium.

Download Metal AM magazine