USA’s largest blockchain-enabled AM machine network to utilise 3YOURMIND software

April 29, 2021

Project DIAMOnD (Distributed, Independent, Agile Manufacturing On-Demand) is a progressive and forward-thinking network established in the US state of Michigan by Automation Alley. Funded by Michigan’s Oakland and Macomb counties, the network has connected over 300 Michigan-based manufacturers in order to accelerate digital transformation and ensure supply chain resiliency.

Automation Alley is the World Economic Forum’s Advanced Manufacturing Hub (AMHUB) for North America and a nonprofit Industry 4.0 knowledge centre said to have a global outlook and a regional focus. Project DIAMOnD has created the nation’s largest network of blockchain-enabled Additive Manufacturing machines and has now begun to utilise 3YOURMIND’s software platform.

The coronavirus (COVID-19) pandemic highlighted significant weaknesses to the traditional manufacturing and supply chain network. Project DIAMOnD, developed in 2020, is reputedly the first programme designed specifically to decentralise the marketplace in the United States. By combining sophisticated technologies, the project hopes to enable manufacturers to produce parts via a vast Additive Manufacturing network at competitive prices with a diverse and flexible supply chain. Partners include Markforged, Watertown, Massachusetts; Microsoft, Autodesk, San Rafael, California; Giggso, and now, 3YOURMIND, Berlin, Germany.

“Distributed manufacturing is the future and we believe that our software platform will enable manufacturers to localise production and leverage domestic expertise,” stated Alexandre Donnadieu, Managing Director at 3YOURMIND. “Our role in this project is to further the digital platform and provide end-to-end workflows that make it much more efficient for OEMs to produce parts on-demand.”

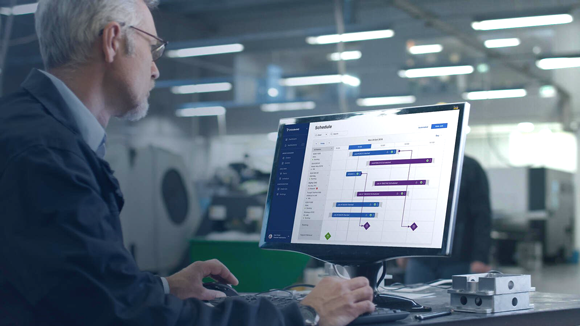

3YOURMIND’s Agile ERP and Agile MES solutions are custom-built software tools that aggregate CAD data and identify AM-ready parts for production. This tool is integrated with a wide variety of AM technologies and materials that enables end-users to coordinate production across multiple facilities; in this particular case, there are 300 Markforged AM machines networked to the DIAMOnD project across the state of Michigan.

“3YOURMIND understands the significance of data transparency and how this leads to new revenue generating opportunities for local businesses,” added Tom Kelly, Automation Alley Executive Director and CEO. “With our established community of 3D printers and 3YOURMIND’s agile manufacturing software, we can coordinate production orders from many different locations and ensure part repeatability.”

On-demand production through distributed manufacturing may become the most economical way to simultaneously improve customer satisfaction and develop a more sustainable model to do so. By removing the logistical costs of shipping, transportation and unnecessary packaging, Project DIAMOnD hopes to act as a blueprint for economical and environmental sustainability.

“In order to accelerate the digital transformation of manufacturing, we must rely on machine learning and technology connectivity,” stated Alexandre Donnadieu, 3YOURMIND. “Blockchain technology supports the digital 3D printing network and our software paves the path for data transparency. We believe that supply chain resiliency is possible with Automation Alley.”

The power of cloud-connected blockchain becomes a strategic tool to connect individual AM machines to a wider network. This flexibility provides disparate manufacturers with the unique ability to collaborate and keep equipment operational 24/7; not only does this provide new revenue streams for manufacturers, but it also keeps production possible when disruptions occur in the future.

Born out of necessity when an international pandemic struck the planet, Automation Alley saw an opportunity to rebuild the future of manufacturing. Project DIAMOnD integrates Additive Manufacturing, automation, IoT, and sophisticated software tools that are collectively designed to enhance distributed manufacturing and further promote the endless possibilities of Industry 4.0.

What began as a network of PPE production partnerships has evolved into a strategic alliance dedicated to eliminating supply chain risks and improving marketplace transparency. 3YOURMIND is the most recent addition to this collection of industrial actors that looks to expand this programme both domestically and internationally.