US Navy selects MELD technology for Additive Manufacturing centre

November 23, 2022

MELD Manufacturing Corporation, Christiansburg, Virginia, USA, has announced that the US Navy has selected MELD’s Additive Manufacturing technology to launch the Navy Additive Manufacturing Center of Excellence at the Institute for Advanced Learning and Research in Danville, California, USA.

The navy showcased the facility that will house their MELD L3 AM machine along with a K2 AM machine. The machines will be placed at the centre to enhance the US Navy’s sixteen-week Accelerated Training in Defense Manufacturing (ATMD) programme. The navy will be working with industry and the Office of the Secretary of Defense to recruit and train individuals with skills in Additive Manufacturing, welding and machining.

MELD explains that its alliance with the navy on this effort helps to enhance the education of students enrolled in their programme by enabling hands-on experience with AM. These skills will be utilised by the US Navy in not only submarine construction, but also shipbuilding.

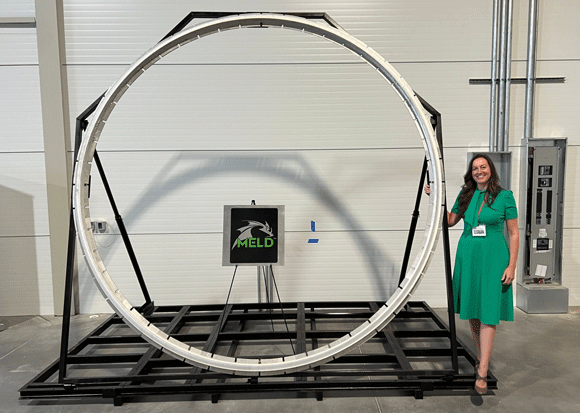

Representatives from the U.S. Navy along with Virginia’s Governor Youngkin and Virginia Congressman Bob Good were at the manufacturing centre for the ribbon-cutting ceremony. At the event, MELD showcased the largest additively manufactured part, a 3-meter tall MELD deposited ring. Nanci Hardwick, MELD CEO, presented Rear Admiral Scott W Pappano and Rear Admiral Jason M Lloyd with MELD deposited parts which demonstrate its capabilities to additively manufacture navy-specific materials including Copper/Nickel (CuNi) and HY80 steel.

MELD uses a patented Additive Manufacturing technology based on a process similar to friction welding, and can be used for the building and repair of metal components using off-the-shelf solid-state materials or powder. The process is capable of additively manufacturing large metal parts due to the fact that it is an open-atmosphere process and is not sensitive to the operating environment or material surface condition.

MELD states that it is committed to supporting the US Navy and bringing added value for a robust workforce and an indestructible supply chain for the US defence sector.