US DoD funds computerised additive friction stir deposition machine at Virginia Tech

January 27, 2023

Virginia Tech, Blacksburg, Virginia, USA, has received a 2023 Defense University Research Instrumentation Program (DURIP) grant to purchase metal Additive Manufacturing technology in an effort to boost education and research in advanced manufacturing and new materials development. This award will fund up to $800,000 for the purchase of a computerised additive friction stir deposition (AFSD) machine that will be housed in Virginia Tech’s Department of Materials Science and Engineering.

“We are grateful to the United States Department of Defense for this award, which will enable Virginia Tech to be at the forefront of advanced manufacturing science and technology. This new system will significantly boost our ability to conduct unprecedented research and meet the needs of interested industrial partners,” stated Suneel Kodambaka, materials science and engineering department head. “This award is proof that our academic and research focus in these areas will not only prepare our students for the careers of the future, but will help spur American innovation in space travel, national defence, health care, and industry.”

Virginia Tech was one of seventy-seven universities to receive a total of $59 million for the purchase of critical research equipment funded this cycle through the federal programme.

“DURIP awards provide essential research infrastructure to enable the pursuit of new knowledge. They help maintain the cutting-edge capabilities of our institutes of higher education,” added Bindu Nair, director of the Basic Research Office in the Office of the Undersecretary of Defense for Research and Engineering. “These awards will sustain the scientific excellence of our universities, train the next generation STEM workforce, and facilitate scientific advances that will build a resilient defence ecosystem.”

The DURIP award is administered jointly by the US Air Force Office of Scientific Research, the Army Research Office and the Office of Naval Research through a merit competition. It is given to university investigators conducting foundational science & engineering research relevant to national defence.

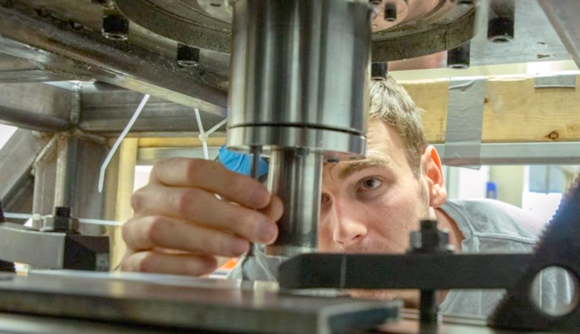

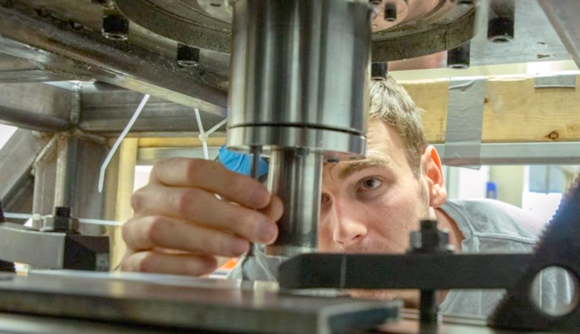

Hang Yu, associate professor of materials science and engineering in the College of Engineering, is the primary investigator on the award. He recently published his first text book on AFSD-related research and has partnered with Additive Manufacturing company Meld Manufacturing.

“This equipment is going to help Virginia Tech to be at the forefront of solid state metal Additive Manufacturing research,” Yu said. “This is transdisciplinary research in nature. You have materials people, you have mechanical people, you have industrial systems people, and you have data science people. And it’s not just research — it’s also about education and workforce development.”

A range of co-primary investigators from several engineering disciplines are named in the award, including Yu’s colleagues in materials science, Alex Aning and Wenjun Cai. Others include Chris Williams in mechanical engineering, James Kong and Xiowei Yue from industrial and systems engineering, Yao Fu in aerospace and ocean engineering, and Dave Higdon from statistics.

Yu’s lab focuses primarily on AFSD, which has drawn great attention recently from the aerospace and defence sectors because of its reputed scalability and the strength of its products. This Additive Manufacturing process can assemble components using metals, such as high-strength aluminium and titanium, without melting them. By building up layers of the materials, AFSD can manufacture components in a range of sizes and shapes that have better strength and fewer defects than components additively manufactured using other processes.

This year, Yu won the prestigious Young Faculty Award from the Defense Advanced Research Projects for his work in this area. The agency will invest up to $1 million over the next three years to devise and test autonomous metals manufacturing and repair processes for austere environments like space. The transdisciplinary research team includes students from materials science and electrical engineering and will use data analytics and artificial intelligence.

Download Metal AM magazine