University of Waterloo and Rio Tinto look to water atomised powder for low-cost Binder Jetting

March 8, 2022

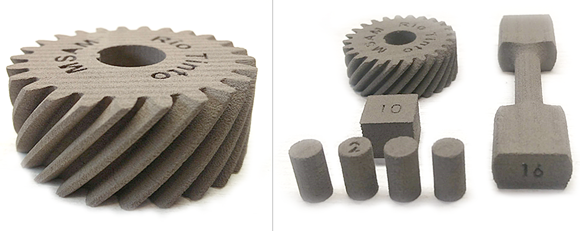

The Multi-Scale Additive Manufacturing Lab (MSAM) at the University of Waterloo, Ontario, Canada, has been working closely with Rio Tinto Metal Powders, located in Sorel-Tracy, Québec, to demonstrate that metal Binder Jetting (BJT) Additive Manufacturing can be deployed as a low-cost and reliable alternative to conventional metal part production. The study has also provided a better understanding of the performance of Rio Tinto’s metal powders when used in BJT.

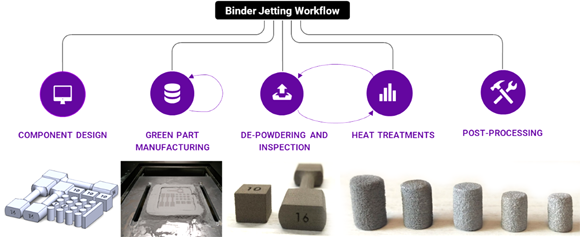

Successful industry adoption of metal AM relies on understanding the complex interactions between design, materials and process to ensure product quality and process reliability. However, the cost of technology adoption, as well as the reliable production of high-quality, defect-free parts, can prove prohibitive. To tackle these challenges, the work has focused on reducing cost barriers by using low-cost water atomised low-alloy steel powders, and enabling robust, fast, process parameter selection and validation to obtain the desired final product quality.

The impact of this project is said to be twofold. Firstly, there is significant academic value in developing thorough process maps for BJT, where the methodology can be easily transferable to other materials and designs. Secondly, there is tremendous potential for this work to influence industrial adoption and drive forward low-cost metal AM part production. This work also has the capacity to promote BJT technology deployment in the wider Powder Metallurgy industry, thereby opening new market sectors for Rio Tinto.

For certain applications, metal BJT may seem less suitable than other metal AM techniques, due in part to comparatively lower part densities and a higher potential for geometric distortion. However, BJT has the potential to be a more cost-effective metal AM technology, when compared to Laser or Electron Beam Powder Bed Fusion (PBF-LB and PBF-EB) for example, due to its speed and scalability – enabling large batches similar to Powder Metallurgy (PM) or Metal Injection Moulding (MIM). This is an attractive incentive for BJT technology adoption in industrial applications, especially in sectors where full density is not required.

Typically, the powders used in metal AM are produced via gas or plasma atomisation, processes that result in highly spherical powders but cost more to produce than the slightly irregular water atomised powders. To leverage low-cost part production, researchers have therefore begun to explore the use of these water atomised powders in Binder Jetting.

Shrinkage resulting from the sintering stage can also be challenging to predict and compensate for. In MIM, this problem has been addressed through sintering and densification studies and approaches such as the concept of a master sinter curve (MSC), an empirical model that captures densification in response to a heat schedule. An MSC can be used to establish a map of the combined BJT process parameters and sintering schedule parameters linked to final part density outcomes. Published R&D on BJT process development and sintering has focused on producing pure Fe components, where target densities above 90% were consistently achieved, with opportunities for further improvements noted [1].

More recent work [2] has focused on constructing MSCs for BJT components manufactured via water atomised and gas atomised AISI 4340 powders, using combined stage sinter theory via dilatometry studies and validation through sintering trials. This study closely examined the densification curves of BJT parts manufactured using these powders in response to heat treatment. The study showed that the densification model can be deployed to predict the outcomes of sintering for both water and gas atomised powder BJT parts with accuracies of 91.2% and 99.4%, respectively. Microstructural examination of both categories of parts revealed similar densification behaviour.

As such, it was shown that there is a high potential for the adoption of low-cost water atomised powders for BJT, and that both the AM process and the sintering process can be tailored to achieve a similar performance to the gas atomised powders.

The ongoing collaborative research aims to provide a low-risk metal AM technology adoption roadmap, as the collaborators are actively looking to expand the feed material library available to metal AM markets. The results of this R&D programme will foster ideas on how to modify and improve the current grades of powders, as well as design new grades to be used in AM. Such collaborative work has the potential to reduce the final cost of metal AM part production.