ULT introduces scalable process gas cleaning to metal AM

December 7, 2022

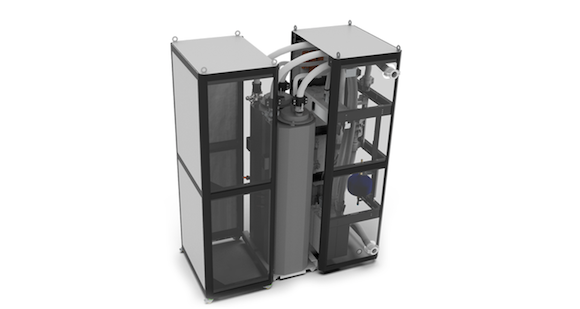

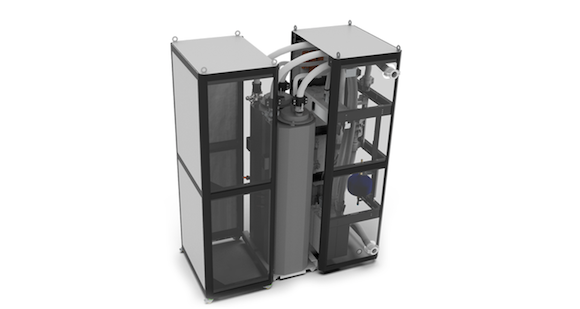

ULT, Löbau, Germany, has introduced a unique solution for process gas cleaning in metal Additive Manufacturing. The AMF 200 is reported to be a modular system developed for the extraction and filtration of process gasses in metal Laser Beam Powder Bed Fusion (PBF-LB) systems of all sizes.

The AMF 200 offers a volume flow of up to 200 m³/h at a vacuum of 10,500 Pa (N2, 50°C) / 15,000 Pa (Ar, 50°C). Due to its scalability, it can be adapted to higher or lower gas flows, regardless of the provider or the volume of the AM machine.

In addition to the small footprint of 800 x 1200 mm and simple operation, the contamination-free filter and powder handling is another reported benefit of the AFM 200. Employees never come into contact with powders or condensates and are therefore protected from skin irritation or allergic reactions.

The machine also offers other features such as automated filter cleaning, the use of a side channel compressor with mounted frequency converter or the use of various sensors (differential pressure filter stages, filter cell fill level, oxygen, volume flow, temperature).

The AMF 200 can be operated both as a slave with an I/O system and as an independent machine run by a specially configured controller.