UK hospital completes jaw reconstruction using bone grafts with metal Additive Manufacturing

October 23, 2017

Morriston Hospital, Swansea, Wales, UK, has reported the success of what it states is the first operation carried out on the National Health Service (NHS) to combine metal Additive Manufacturing with traditional bone grafts. The aim of the operation was to remove and rebuild a section of the patient’s lower jawbone following the discovery of a tumour, which had grown large enough to risk breaking the jaw.

Traditionally, surgeons have replaced jawbones with a section of the fibula bone, taken from the leg. However, this method makes it very difficult to retain the aesthetic shape of the patient’s jaw. In order to maintain the patient’s original jawline, the new bone must be set too low to allow for dental implants; to be set high enough to allow implants, the shape of the jaw must be sacrificed.

In addition, this method involves trimming the new bone and fixing it in place with a metal plate which the surgeon bends by eye during surgery. As a result, surgeries such as this one can take up to ten hours.

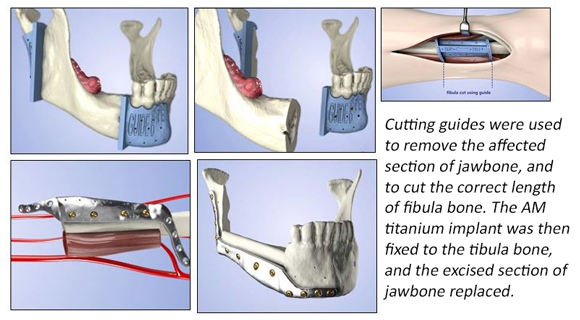

Morriston Hospital states that its team designed an anatomically-correct titanium implant directly from CT imaging taken from the patient’s existing jawbone, which was then metal additively manufactured exactly to shape. The implant was designed to maintain the aesthetic shape of the jawline while fixing the fibula bone in place, without the need to bend it to shape during surgery.

Using the same scans, the team also created accurate cutting guides to enable it to excise the exact length of bone required from the fibula, matching the removed section of jaw.

Peter Llewelyn Evans, Maxillofacial Laboratory Services Manager at Morriston Hospital, stated, “We used the CT image of the patient’s jaw on the other side and mirrored it, and the design of the implant and cutting guides is based on that shape. The titanium implant fits the patient’s jaw perfectly without the surgeon having to do any adjustment. Similarly, using cutting guides means the section of fibula exactly matches the section of jawbone removed.”

Madhav Kittur, a member of the surgical team which developed the surgery, stated that five matching procedures have been carried out at Morriston since the first, with a sixth in the planning stage. “It has taken away the uncertainty,” he explained. “We know exactly what is going to happen before we go into theatre as everything is computer planned. This can save up to two hours. On average this operation takes eight to ten hours, so when we take two hours out of that it is quite a sizable reduction.”

“This is a big advance,” he continued. “It’s better aesthetically, the patient is under anaesthetic for less time, and recovery is better. Although we haven’t yet measured it, I would even say that the length of stay in hospital is also reduced.”

The team has published technical information on the procedure in the British Journal of Oral and Maxillofacial Surgery.