TU Graz develops new steel powder for Additive Manufacturing

July 1, 2019

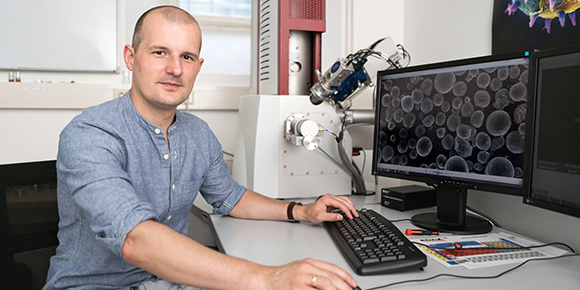

Mateusz Skalon has developed a new steel powder for Additive Manufacturing and is now working on its comercialisation (Courtesy TU Graz/IMAT)

Researchers at Graz University of Technology (TU Graz), Austria, have developed a steel powder for Additive Manufacturing which is reported to help simplify the production of complex components. In a spin-off funding programme, work is now being undertaken to bring the new metal powder to market.

Mateusz Skalon, of TU Graz’s Institute of Materials Science, Joining and Forming, reportedly modified the particle surfaces of conventional 316L stainless steel powder so that the metal liquefied by the laser beam during Laser Powder Bed Fusion (L-PBF) behaves in a more stable way. This allows greater freedom of design, since components with low angles of inclination do not collapse during printing.

Titled NewGen SLM powder, the new material is said to require fewer supporting structures, which account for up to 20% of the total production cost of a typical L-PBF part. Skalon stated, “Cost savings of up to €114 can be achieved per each kilo of printed metal.” This also impacts on the sustainability of the process, as surplus stainless steel powder can be recycled easily following production.

Scaling for market maturity

Skalon stated that he wants to implement the results of his research in a business capacity with the support of TU Graz. In the framework of the current Spin-Off Fellowship of the Austrian Research Promotion Agency, he is scaling the modification process to bring it to market maturity.

“We’ll be testing the powder on the most common laser melting systems in the next sixteen months. Basing on this, we want to establish a production company in Austria directly after the Fellowship where purchased 316L stainless steel powder will be modified and sold,” Skalon stated. “Target groups will include manufacturers of highly complex metal parts, manufacturing companies in the automotive, aircraft and mechanical engineering sectors as well as research institutions dealing with additive manufacturing methods. We have already had expressions of interest from business and industry.”

Skalon’s research has been supported by Christof Sommitsch, head of TU Graz’s Institute of Materials Science, Joining and Forming, as Project Supervisor, and Christoph Kovacic, Chairman of Junge Wirtschaft Steiermark, as a mentor, Stefan Vorbach, the head of TU Graz’s Institute of General Management and Organisation, and institute staff Martin Glinik and Elisabeth Poandl.