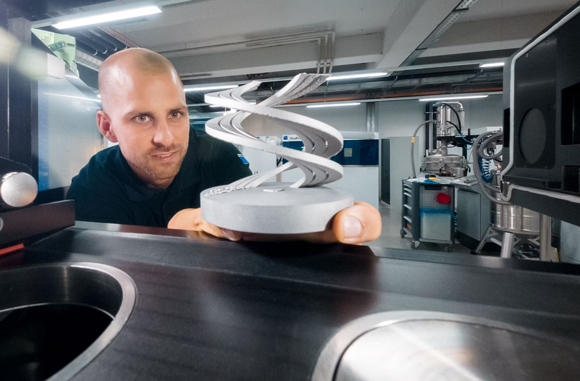

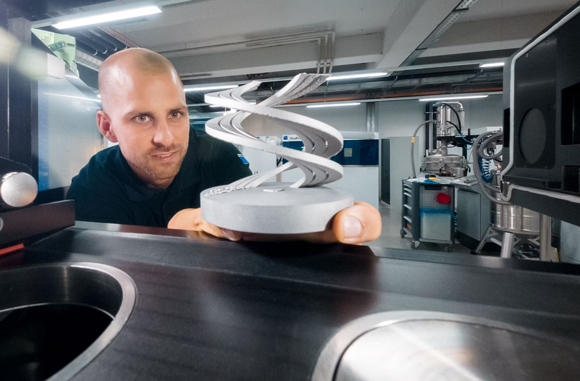

Trumpf’s updated support-free Additive Manufacturing technology reduces waste and opens up new applications

September 12, 2023

Trumpf, located in Ditzingen, Germany, has reported updates to its TruTops Print Additive Manufacturing software, enabling users build parts with overhang angles as low as 15º without requiring support structures.

Typically, these structures provide support for parts that feature cavities or overhangs, anchoring these to the build platform. Support structures also help to dissipate heat from the part and prevent internal tensions and deformations during manufacturing.

However, Trumpf’s new technology is reported to allow for many AM applications to be carried out without supports, even when working with hard-to-process materials like stainless steel.

TruTops Print enables Additive Manufacturing machines to use the optimal manufacturing process for each different area of a part, eliminating the need for support structures. Additionally, Trumpf’s new AM machines feature improved gas flow, resulting in uniform processing conditions and support-free manufacturing.

“When we 3D print a part, we want as much control as possible over when and where the material melts and re-solidifies. The skill lies in choosing the right exposure strategies to prevent internal tensions and overheating in the overhang region,” stated Timo Degen, product manager for Additive Manufacturing at Trumpf.

“Users from any industry can benefit from the ability to 3D print parts without supports. The advantages of support-free printing are particularly appealing for parts that feature large cavities or challenging overhangs,” Degen added. Examples include tanks, heat exchangers, hydraulic blocks and tool moulds.

The new technology also enables new applications that were not feasible when support structures were necessary, such as additively manufactured radial compressors and shrouded impellers. Previously, manufacturers could not build support-free impellers due to their overhang angles. “The need for supports meant that 3D printing wasn’t an economically viable alternative to conventional manufacturing. But now things are different,” Degen concluded.

Trumpf will showcase this new technology at EMO Hannover 2023 exhibition, scheduled to take place September 18-23, 2023.

Download Metal AM magazine