Trumpf to introduce updated TruPrint 2000 metal Additive Manufacturing machine at Formnext

November 7, 2023

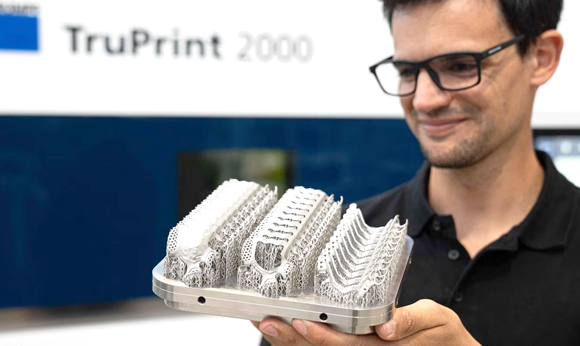

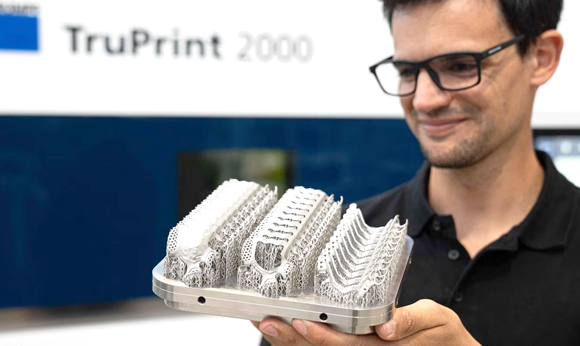

Trumpf, located in Ditzingen, Germany, has increased the productivity of its TruPrint 2000 metal Additive Manufacturing machine, and will showcase the new model at this year’s Formnext exhibition. The updated Laser Beam Powder Bed Fusion (PBF-LB) machine is now equipped with a square build plate instead of a round one, and offers increased laser power options with two 500 watt fibre lasers, as an alternative to the 300 watt laser basic configuration.

“The 3D printer is now also designed for mass production. Users from all industries benefit from the machine’s high productivity,” stated Mirko De Boni, product manager at TRUMPF responsible for the TruPrint 2000.

The updated TruPrint 2000 has a build volume of 200 x 200 x 200 mm and, with an optimised optical design, both lasers can process the entire build plate simultaneously. This is said to greatly improves productivity and enables dental technology companies, for example, to manufacture up to 36% more removable partial dentures on the square build plate than on a comparable round build plate. The machine’s increased surface area and laser power are also an advantage in tool and mould making, adds Trumpf.

“The TruPrint 2000 not only works very productively, but also precisely and with the highest quality,” added De Boni. “Safety is the top priority for Trumpf 3D printing, especially for critical areas such as medical technology. With the upgrade of the TruPrint 2000, patients receive high-quality implants with even more long-term stability.”

A motorised beam expander allows the TruPrint 2000 to automatically adjust the spot diameter of the laser to either 55 or 80 µm. The 80 µm diameter enables higher productivity, while the 55 µm diameter can be used when special metal powders require a higher energy density.

WIth this update, the TruPrint 2000 now shares the same process capabilities as other Trumpf AM machines, driven by the 80 µm beam size and the optimised gas-flux. “With this standardisation, users can now easily transfer the parameters for printing their parts from machine to machine, such as from a TruPrint 2000 to a TruPrint 1000 or TruPrint 3000, allowing for more flexible manufacturing,” confirmed De Boni.

Trumpf is presenting the updated machine for the first time at Formnext at Hall 12, D81.

Download Metal AM magazine