Trumpf highlights use cases for 500 and 700 W laser power TruPrint 3000

August 4, 2023

The optimisation of laser power in Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing has become an increasingly critical consideration over the years. Trumpf, Ditzingen, Germany, recently made the case for increased laser power and explained how the company is leveraging this increase in an effort to optimise efficiency.

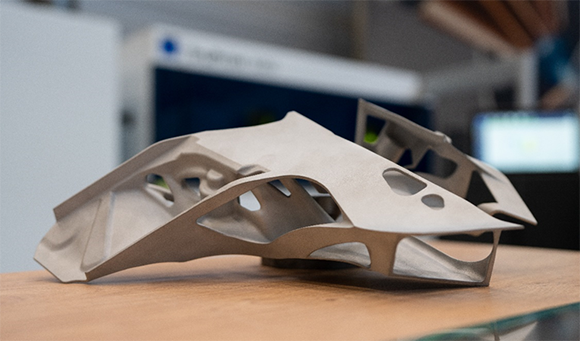

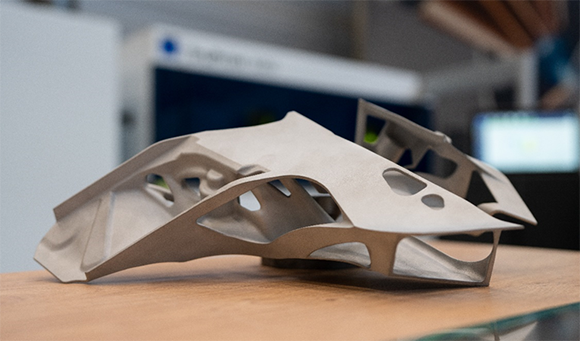

The company recently expanded the line up of its TruPrint Series 3000, offering both a 500 and 700 W laser across the series to better match the varying productivity needs of customers. The 700 W model is, the company states, able to reduce part build time by 1.4 X compared to the 500 W model, thus reducing cost per part, making it well suited to markets which face increasing demand for mass-produced products (e.g., automotive).

Roland Spiegelhalder, Additive Manufacturing Production Manager at Trumpf, stated, “This means less time per part. Output is increased by more than a third, and the cost per part is drastically reduced. In some cases, it is even better to use just one 700 watt machine than two with 500 watts each. This saves a lot of space and personnel.”

This increase in power, however, can raise concerns about higher build temperatures and, thus, material compatibility. Spiegelhalder stated, however, that all powders suitable for use with the 500 W laser machines are also suitable for the 700 W laser machine through ‘downward compatability’, which enables users to lessen the power levels as necessary. This, it was emphasised, does not negate the use cases for the less expensive 500 W TruPrint3000 machines; if speed and higher power levels aren’t of the utmost concern, the 500 W machines remain ideal.

“All powders used in 500 watt laser printers can also be processed in 700 watt machines without difficulty. Sometimes they can be processed even more productively: for example, materials such as aluminium cast alloy or high-strength titanium alloys. Furthermore, there are now powders on the market that cope particularly well with the high power levels and enable even faster build rates and better part quality than standard powders, for example, Equispheres’ AlSi10Mg aluminium powder,” he stated.

“You need to ask very basic questions when making an investment decision,” Spiegelhalder explained. “Most importantly: what does the machine cost per part? But also: is it possible that I will have to produce more parts in future than I am aware of at the moment? How variable does my production have to be? Am I at risk of losing orders due to a lack of speed?”

Download Metal AM magazine