Trumpf expands opportunities in medical, aerospace and automated engineering

December 19, 2022

Trumpf, Ditzingen, Germany, has announced a number of developments to its metal Additive Manufacturing machines intended to create further opportunities in the medical, aerospace and automated engineering sectors. Key changes include the addition of a multi-plate function on the TruPrint 1000 – enabling the machine to be used for series production – and the expansion of its powder alloys selection.

The introduction of the multi-plate function is said to have made the machine twice as fast as its predecessor. Users can stack up to four build plates, on top of each other in the build cylinder, onto which the system additively manufactures components one after the other. This allows the TruPrint 1000 to be suitable for lights-out production, saving time and costs.

Via use of an exchange kit, users can also change the build, powder and overflow cylinders of the TruPrint 1000 in 15-20 minutes using integrated gloves. The filters are accessible on the side of the machine. Without opening the door, the user can clean the additively manufactured components and unpack the build job; a big advantage from a health and safety perspective. Trumpf is also said to have Improved the machine’s gas flow in an effort to make it faster and more reliable.

In the multi-laser variant of the TruPrint 1000, the system has two lasers which can process the entire build plate. The machine also uses a beam expander to automatically adjust the spot diameter of the laser – 55 or 80 micrometers – to suit the particular build job. The wider spot allows for higher productivity, while the 55 micrometer alternative can be used when special powders need higher energy density.

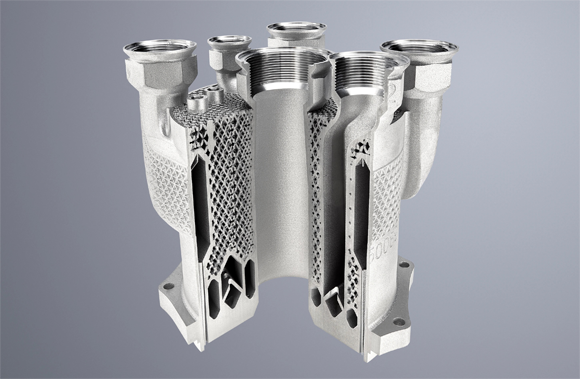

Continued close collaboration with powder manufacturers has also enabled Trumpf to expand its material selection to include titanium, aluminium, stainless steel and tool steel alloys for the TruPrint 3D machines. This is hoped to allow users to implement new applications using Additive Manufacturing or improve existing applications with new powders – for example, the new titanium alloy allows users to process titanium 6242, a common request from the aerospace, motorsport and energy industries.

For the automotive industry, Trumpf’s CustAlloy aluminium alloy from ECKA Granules is said to be particularly beneficial, as the limitations of standard aluminium are being reached within the industry. CustAlloy has very good mechanical properties and does not break or crack as quickly as traditional aluminium, making crash-relevant applications possible. At the same time, CustAlloy is less expensive to purchase than comparable high-end aluminium alloys, which use expensive alloying elements to achieve their properties.

Recently, Trumpf qualified the Printdur HSA stainless steel alloy for the TruPrint 2000. Made from recycled scrap, this powder is sustainable and noted as being particularly strong without thermal post-treatment and does not rust as quickly. The Medidur alloy has the same properties as Printdur HSA, though Printdur developed this material especially to meet the medical industry’s high-purity standards.

Completing the new powder additions is TRUMPF’s M789 tool steel, particularly suited to tool and mould making. Without preheating the powder, users can use it to additively manufacture components.