Toolcraft AG extends its Additive Manufacturing fleet with Trumpf TruPrint 3000

February 15, 2024

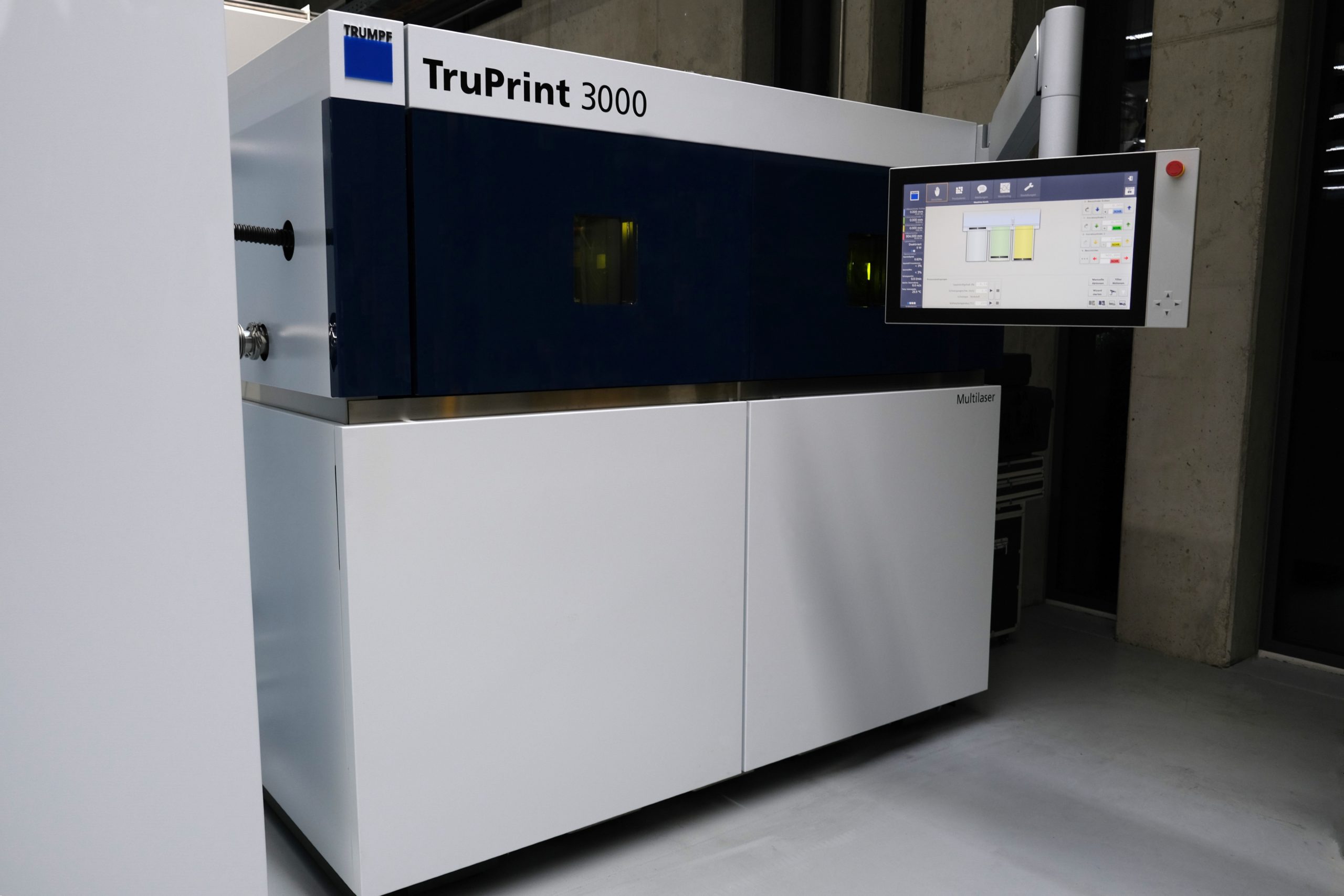

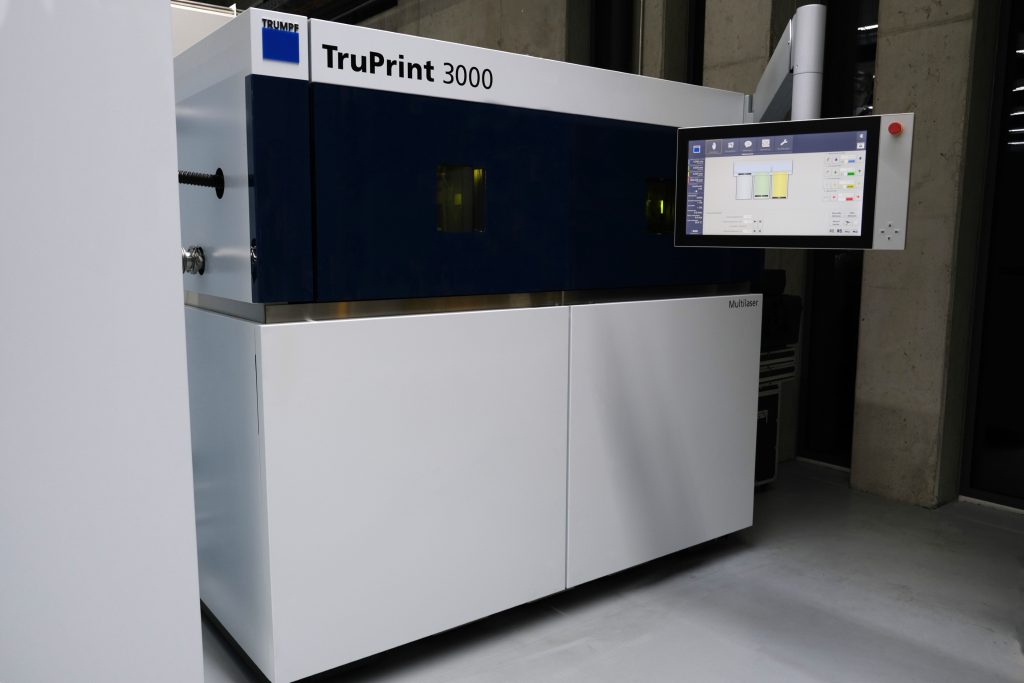

toolcraft AG, based in Georgensgmünd, Germany, has added a new Trumpf TruPrint 3000 to its fleet of ten Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machines. The company also announced its Additive Manufacturing with TruPrint machines has been certified in accordance with ISO/ASTM TS 52930:2011 and 52920:2013, according to requirements for industrial AM processes, qualification principles, and production sites. This certification is important for systems that are used in the medical engineering, aerospace and semiconductor sectors.

The new TruPrint 3000 is a medium-format (PBF-LB) Additive Manufacturing machine with industrial part and powder management. The TruPrint 3000 incorporates two lasers and has a build volume comprising a diameter of 300 mm and a height of 400 mm.

“Stable processes, reproducibility, service and data security were important criteria for us during the decision-making process. As a long-standing partner, Trumpf has proven itself time and time again over our many years of working together and totally convinced us on all these points,” stated Stefan Auernhammer, Additive Manufacturing Business Unit Manager at toolcraft.

toolcraft is primarily planning to use its new machine for series production in the semiconductor, aviation and pressure equipment sectors.

“We want to use the integrated melt pool monitoring system to expand our knowledge of the process and we are confident that we can take the quality, reliability and efficiency of the melting process to the next level,” added Auernhammer.

Download Metal AM magazine