Titomic signs MoU to distribute Titanium Kinetic Fusion systems in Japan & South Korea

April 23, 2019

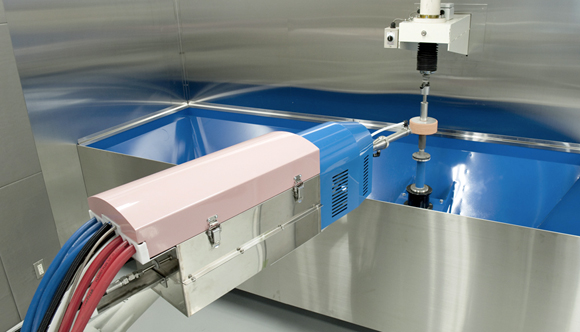

The TKF process applies titanium and titanium alloy powders onto a scaffold surface to rapidly produce titanium or titanium or titanium/composite products and parts (Courtesy Titomic)

Titomic Limited, a metal Additive Manufacturing company based in Melbourne, Australia, has initiated a Memorandum of Understanding (MoU) with Osaka Titanium Technologies Co., Ltd., Amagasaki, Hyōgo Prefecture, Japan, and the Marubeni Corporation, Nihonbashi, Chuo, Tokyo, Japan, to distribute its Titomic Kinetic Fusion (TKF) systems in Japan and South Korea and supply aerospace-grade gas atomised titanium powders globally.

The TKF process applies titanium and titanium alloy powders onto a scaffold surface to rapidly produce titanium or titanium/composite products and parts. Due to the nature of the process, powder particles do not need to be of a uniform micron size, as is required in alternative AM techniques. Titomic states that the cost of this powder is approximately 1/5 to 1/10th that of traditional AM powders, resulting in components up to 50% cheaper.

The agreement with Osaka Titanium Technologies Co. and Marubeni is expected to help further Titomic’s market development by enhancing TKF systems distribution, metal powder supply, and creating new market applications. According to Titomic, implementing these strategies will provide the company with an expanded global network for TKF system distribution and production run demand; a secured supply chain for metal powders required for high-value applications; and ongoing access to material science and next-generation titanium alloy powders for TKF systems.

“Titomic’s partnering with OTC and Marubeni secures supply of the highest-quality aerospace-grade titanium powder, from a reputable global corporation, aligning with Titomic’s development strategies in Aerospace and Defence,” stated Jeff Lang, Managing Director at Titomic. “This partnership will enable the development of new titanium powder technologies which, when combined with Titomic’s TKF automated production systems, drives new revenue opportunities through high-volume production of titanium parts for automotive and heavy industries.”

Yusuke Yamamoto, General Manager at Marubeni, commented, “Marubeni has been supplying titanium raw materials to OTC for decades. We’re very happy to have this opportunity to support OTC and Titomic in a new field of titanium powder. We believe the demand for TKF system and powder supply has significant potential in the future. We also believe we will have great success through combining Titomic’s leading-edge technology, OTC’s high-quality titanium powder and our network in the world.”

Osaka Titanium Technologies’ Managing Executive Officer, Yoshihisa Ohashi, added, “OTC is proud to announce our partnering with Titomic for supplying Titanium powder for the TKF system. We appreciate that Titomic identifies OTC as being such a high-quality producer of titanium powder with a long-history of being a global leading producer in high-quality titanium sponge. We are excited to be collaborating with such an innovative global leader of industrial scale, high-volume Additive Manufacturing as Titomic and are keen to create new commercial opportunities for titanium powder which can currently only be realised using the TKF process.”