Titomic appoints John Barnes Non-Executive Director of the Board

February 5, 2018

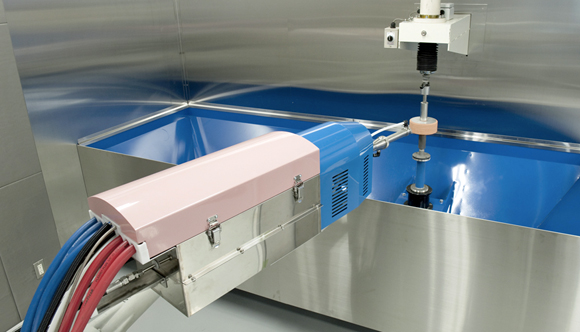

Titomic’s TKF process applies titanium and titanium alloy powders onto a scaffold surface to rapidly produce titanium or titanium/composite products and parts (Courtesy Titomic)

Titomic, a provider of large-scale metal Additive Manufacturing technology based in Melbourne, Australia, has announced the appointment of John Barnes as Non-Executive Director of the Board of Titomic Limited. Barnes is currently Managing Director of The Barnes Group Advisors, and has a background in aerospace and Additive Manufacturing.

Barnes’ previous roles include Vice President of Advanced Manufacturing at Arconic, Director of the Australian-based Commonwealth Scientific and Industrial Research Organisation (CSIRO), Senior Manager at Lockheed Martin Skunk Works™ and Program Manager at Honeywell Engines. He established The Barnes Group Advisors, a speciality engineering firm which aids companies in the advancement of Additive Manufacturing, in 2017.

Over the course of his career, Barnes is said to have developed his expertise in manufacturing, airframe structures, gas turbines and stealth technology. His teams have reportedly implemented technology on the F-22, F-35 and Airbus A350, as well as providing solutions to medical patients requiring heel and thoracic replacements.

“I’m really excited to be part of Titomic’s journey and am looking forward to combining my interests in 3D printing, titanium and product development,” Barnes stated. Titomic Chairman, Philip Vafiadis, commented, “John Barnes is one of Additive Manufacturing’s global leaders. His knowledge, expertise and adept strategic planning in the industry ensure he will be an invaluable asset as Titomic embarks on transforming design and manufacturing.”

Titomic is currently commercialising a process capable of additively manufacturing large-scale titanium parts that it claims will be thirty times faster than other metal Additive Manufacturing processes. The new technology, which it calls Titomic Kinetic Fusion (TKF), was jointly developed by Commonwealth Scientific and Industrial Research Organisation (CSIRO) and Force Industries.

The TKF process applies titanium and titanium alloy powders onto a scaffold surface to rapidly produce titanium or titanium/composite products and parts. Due to the nature of the process, powder particles do not need to be of a uniform micron size, as is required in alternative AM techniques. Titomic states that the cost of this powder is approximately 1/5 to 1/10th that of traditional AM powders, resulting in components up to 50% cheaper.