Tamper-proof software for Additive Manufacturing files receives patent

July 28, 2017

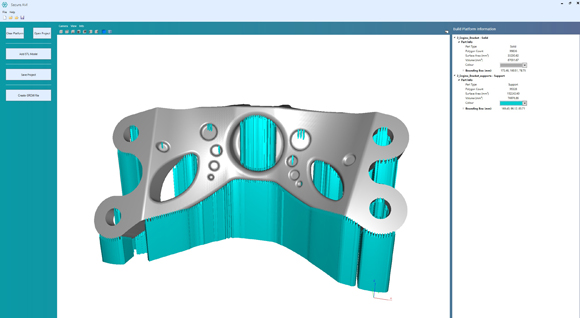

Grow’s Additive Manufacturing software (Courtesy Grow Software Ltd)

Grow Software Ltd, London, UK, has received a US patent for its secure software for Additive Manufacturing (3D Printing) files. According to the company, its patent provides a method for the secure and consistent manufacture of AM designs, in a controlled manner, at a remote location.

During the development and transfer of digital design files for distributed Additive Manufacturing, valuable product data can be vulnerable to security concerns and accidental alterations. The security of product design data is especially important in the aerospace and defence industries, while medical devices are particularly sensitive to the small parameter adjustments which could be made accidentally during file loading.

Using Grow’s software, a 3D model and its machine process instructions are combined to create an additive design file containing all of the information needed to manufacture the part. This design file is encrypted prior to transfer to the manufacturing location. Once received, the build location is authorised and model and build instructions transmitted directly to the Additive Manufacturing machine being used, without allowing access to the design file.

According to Grow, this will allow products to be manufactured exactly to their designer’s requirements and could minimise the need for quality assessment. Using Grow’s software, no third party will have the opportunity to access any product geometries or intervene with the original design at any stage. In addition, users will be able to verify and trace authorisations by tracking each build, receive automated reports on manufacturing events and access all information necessary to perform Quality Assurance on their final product.

Grow Software Ltd was initially developed at Autodesk subsidiary Within Labs, and its early distributed manufacturing software was integrated with EOS and Arcam. The company believes that the impact of its latest technology on the Additive Manufacturing industry will be significant, as corporations begin to recognise and address the challenges of secure distribute manufacturing.