STELIA Aerospace demonstrates additively manufactured aircraft fuselage panels

February 19, 2018

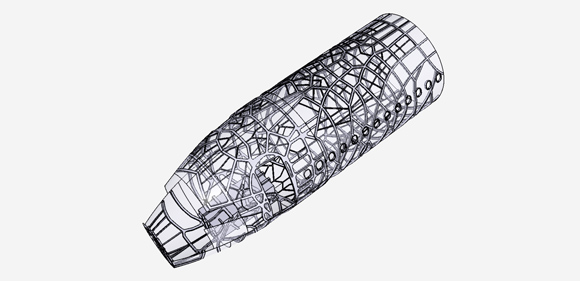

Diagram showing the architecture of a fuselage produced using WAAM, with stiffeners manufactured directly on the surface (Courtesy STELIA Aerospace)

STELIA Aerospace, Toulouse, France, has produced a demonstrator part for wire-arc additively manufactured (WAAM) fuselage panels, made in aluminium with stiffeners manufactured directly on the surface. The part was produced as part of the R&T project DEFACTO (DEveloppement de la Fabrication Additive pour Composant TOpologique), on which STELIA is collaborating with aluminium product specialist Constellium, Centrale Nantes engineering school and the engineering group CT Ingénierie.

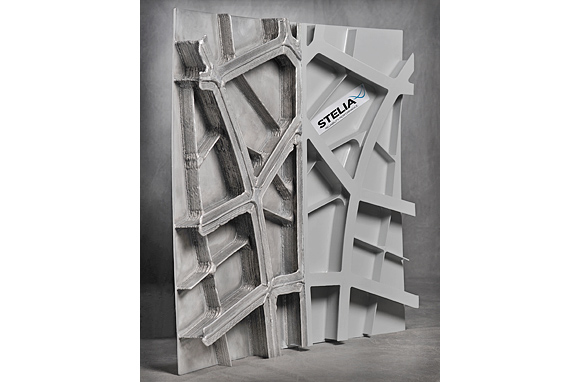

The company expects that the new production method should, in the long term, eliminate the need for added stiffeners, which are either screwed or welded to the fuselage panels. The demonstration part measures 1 m2 and was manufactured by depositing layers of aluminium wire welded by electric arc. The new design was derived from fuselage topological optimisation studies carried out by STELIA and CT Ingénierie over several years.

STELIA Aerospace, an Airbus-owned company, designs and manufactures the front fuselage sections for the entire Airbus family of aircraft, as well as fuselage sections and specific sub-assemblies for Airbus, fully-equipped wings for ATR, fully-equipped central fuselages for Bombardier’s Global7000 and complex metallic and composite aerostructure parts for companies including Boeing, Bombardier, Embraer and Northrop-Grumman.

STELIA Aerospace’s 1 m2 aluminium WAAM demonstrator part (Courtesy STELIA Aerospace)

The company launched the DEFACTO project in 2017 as part of a research strategy, at which time it began topological optimisation studies with the aim of additively manufacturing demonstrator parts for elementary components (such as fittings), large dimension parts (frames) and large sub-assemblies. The project is co-financed by the French Directorate General for Civil Aviation (DGAC) and expected to run for two and a half years.

Among the benefits targeted by the project are the integration of part functions, a reduction in ecological impact, component weight, material use and manufacturing cost. Cédric Gautier, CEO of STELIA Aerospace, explained, “With this additively manufactured demonstrator, STELIA Aerospace aims to provide its customers with innovative designs of very large structural parts derived from new calculation methods (topological optimisation).”

“Through its R&T department, and thanks to its partners, STELIA Aerospace is therefore preparing the future of aeronautics, with a view to developing technologies that are always more innovative and will directly impact our core business, aerostructures,” he concluded.