Solukon launches software for intelligent depowdering of AM parts

October 27, 2022

Solukon, Augsburg, Germany, will present its automatic depowdering software, SPR-Pathfinder®, at Formnext 2022 in Frankfurt, Germany, November 15–18, 2022. By commercialising this software, the company aims to reinforce its role as a pioneer in industrialised, automatic depowdering.

The increasingly complex applications of powder-based metal Additive Manufacturing have led to increasing demands on industrial depowdering. Last year, the company introduced its Digital-Factory-Tool, a sensor and interface kit for quality assurance and automation integration. Now, with the SPR-Pathfinder, the company aims to make automated depowdering solutions more accessible to the wider market.

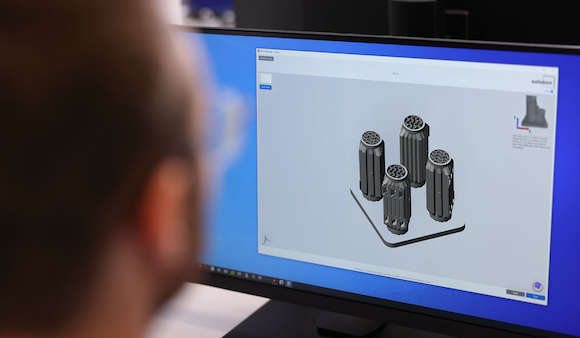

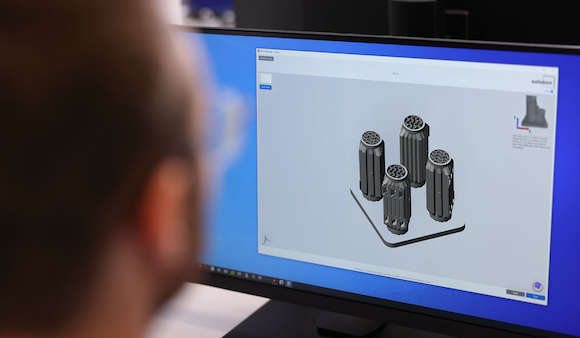

To remove excess powder from complex internal structures, SPR-Pathfinder uses the build job’s CAD file to calculate the ideal motion sequence in the Solukon system. The SPR-Pathfinder calculations are based on a flow simulation that analyses the part’s digital twin – Solukon believes this is the first time a digital twin of a part has been made available in AM post-processing.

The individually calculated motion sequence is then read by the Solukon system, which in turn runs the programmed paths. This ensures that even the most complex parts are cleaned, quickly and without any human programming effort.

“In contrast to conventional manufacturing processes, 3D printing uses the part’s digital twin. To date, however, this was only utilised during the printing itself. With SPR-Pathfinder, the part’s digital twin can now also be used during depowdering. This is how we ensure that the potential of the digital twin can be used to the fullest in postprocessing as well,” says Andreas Hartmann, CEO/CTO of Solukon.

SPR-Pathfinder: a background

The software used in SPR-Pathfinder was developed by Siemens Technology in 2018, in a joint project with Solukon, and unveiled publicly for the first time under the name SiDAM. The principal developer was Dr Christoph Kiener, Siemens Technology. Solukon and Siemens received the TCT Postprocessing Award 2019 for their use of the software in a Solukon SFM-AT800-S depowdering system.

Until recently, the software prototype was available only to a select number of Siemens’ and Solukon’s development partners. Now, Solukon has acquired the exclusive rights to the software, developed it into a Solukon product, and is bringing it to the AM market under its new name, enabling its customers to purchase licenses for the first time.

“It’s a logical step for us to license the depowdering software exclusively to Solukon, thereby enabling the pioneer in industrial depowdering to offer the market an even more effective product,” explained Dr Georg Bodammer, Senior Venture Director at Siemens Technology Accelerator. “This way, customers can get everything from a single source: the market-leading depowdering system and the exclusive, intelligent software.”

The name of the technology reflects the established depowdering technology Smart Powder Recuperation, also known as SPR. SPR generally involves automated rotation on two axes as well as adjustable vibration in a safety-controlled atmosphere. The algorithm-based SPR-Pathfinder calculates the ideal motion sequence for the most complex geometries, finding the best path to allow the powder to flow out of the part completely.

The software can currently run on SFM-AT800-S and SFM-AT1000-S models – starting with serial number 1 of those models. “It is very important to us that the widest possible customer base can benefit from our software from the moment it hits the market,” stated Andreas Hartmann, CEO and CTO at Solukon. In the future, the company expects that the software should also be compatible with other models, such as the SFM-AT350.

SPR-Pathfinder runs as on-premises software – in other words, on the customer’s own PC or notebook device, not in the cloud. Each license is bound to a device and is always valid for the current version at the time of purchase.

A customer-validated solution

Prior to market launch, Solukon had the software thoroughly tested by several notable pilot customers, including Siemens Energy in Berlin, which has been using software for quite some time as part of a joint development project.

The AM team in Berlin manufactures hot gas parts in series using AM and has been employing a Solukon SFM-AT800-S for its depowdering needs for the past two and a half years. “With SPR-Pathfinder, we can depowder in series without any manual programming,” stated Julius Schurb, Project Leader for IDEA at Siemens Energy.

“The parts are guaranteed to be clean and this guarantee, in turn, allows us complete freedom in part design. Furthermore, we save a lot of time, which we can then dedicate to other value-adding activities in the manufacturing process,” he concluded.

The Solukon team looks forward to welcoming visitors at Booth 12.0, B21. In addition to the new software, all four of Solukon’s depowdering machines will be on display.