Solukon equips SFM-AT200 with ultrasonic excitation for improved depowdering

August 19, 2021

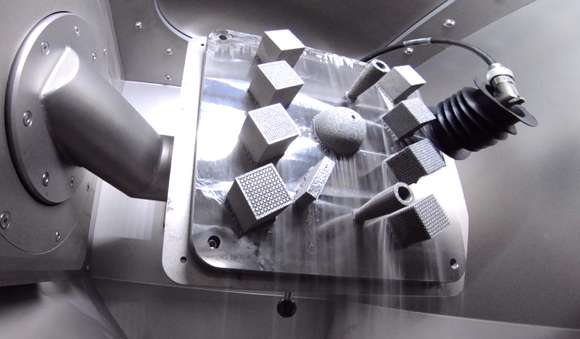

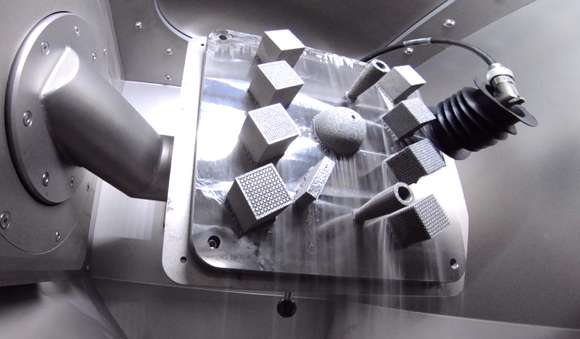

Solukon Maschinenbau GmbH, Augsburg, Germany has added ultrasonic excitation to its its entry-level depowdering machine, the SFM-AT200. This new feature aims to completely depowder more challenging geometries, such as medical components with lattice structures, including those with particularly narrow internal channels or porous structures.

Electric frequency excitation in the ultrasonic range is said to make the powder flowable – allowing the powder to flow out of very small channels within seconds. In combination with the fast inertisation of the system, components can be reproducibly cleaned within a few minutes.

For testing the new excitation system, Solukon collaborated with the medical technology experts from the Swiss m4m Center, located in Bettlach, Switzerland. Recently certified with the ISO 13485:2016 standard for medical devices, the centre is an authorised consulting partner for Additive Manufacturing of medical devices, such as implants or joint prostheses.

Swiss m4m Center provided medical components for testing the new ultrasonic excitation within the Solukon SFM-AT200. In equivalence to the American standard ASTM F33F, these parts have extremely fine internal channels and cavities, making them ideal for testing frequency excitation under real conditions.

The reported results revealed that the ultrasonically excited SFM-AT200 completely depowders the test components within a few minutes.

“Frequency excitation further shortens the already short process time of the SFM-AT200 when cleaning medical components. Now, powder flows out of lattice structures, too. Automatic depowdering with the SFM-AT200 is a real door-opener for validated post-processing,” stated Nicolas Bouduban, CEO of Swiss m4m Center.

Frequency excitation will be available as an option for the SFM-AT200 from autumn of this year.