Solar Atmospheres retrofits vacuum furnace for MIM and sinter-based AM

September 28, 2021

Solar Atmospheres of Western PA, Hermitage, Pennsylvania, USA, reports it has successfully retrofitted a pre-owned vacuum furnace with a new hot zone and pumping technology to enable the furnace to be used for Metal Injection Moulding and sinter-based Additive Manufacturing processing. The upgrade is designed to minimise the impact of detrimental binders on the furnace during sintering cycles.

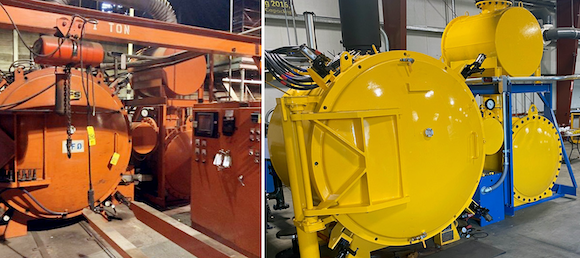

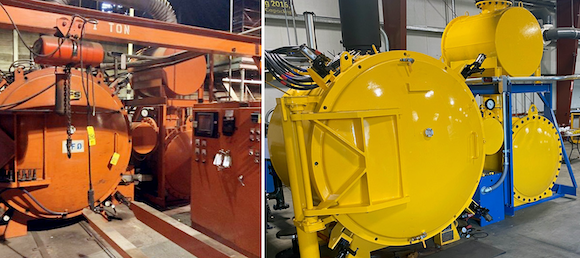

For the project, the company purchased a used VFS HL50 external quench vacuum furnace at auction, with the specific goal of retrofitting an older furnace with new technology. Solar Manufacturing, based in Sellersville, Pennsylvania, and led by owner and CEO William Jones, designed the apparatus needed to consolidate the binders into one central location, thus minimising the cleaning downtime often experienced.

The update included a completely new hot zone, a binder pumping port and a second vacuum pump.

The company stated that, by mid-October, high-volume MIM sinter jobs will be fully transferred from current Solar vacuum furnaces to this dedicated and refurbished vacuum furnace. After multiple sintering runs, Solar will then have the data to compare the downtime of a traditional vacuum furnace versus the newly designed debind & sinter modifications. Solar added that it intends to share its findings after the completion of these test runs.