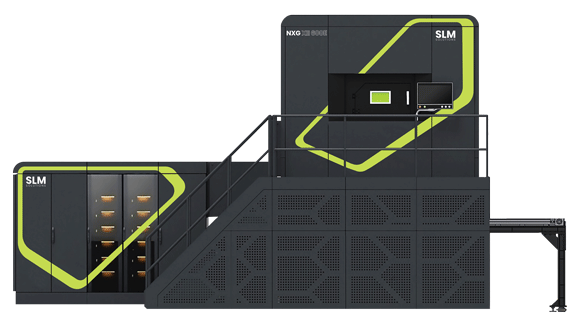

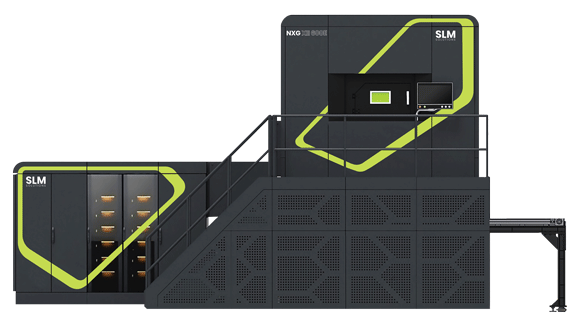

SLM Solutions announces NXG XII 600E featuring extended build envelope

November 9, 2022

SLM Solutions Group AG, Lübeck, Germany, has announced its latest Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machine: the NXG XII 600E. Based on the NXG XII 600, the NXG XII 600E features an extended 1.5 m build envelope in the Z-axis, reportedly exceeding the size of its nearest competitor’s Z-build envelope by 50%. The company has accepted its first order for the new machine from Concurrent Technologies Corporation (CTC), the prime contractor for a US Air Force Research Laboratory (AFRL) project.

AFRL funded this work to leverage Additive Manufacturing for advanced DoD applications. Customers who already have an NXG XII 600 AM machine installed, or are about to install one, have the option to upgrade their original AM machine to expand the Z-build envelope. Delivery of the NXG XII 600E is expected in 2023.

Customers in the metal Additive Manufacturing industry are demanding larger metal parts – and faster. Serial production of complex geometries can now be completed in hours or days rather than weeks and months. To meet these industry expectations, the NXG XII 600E is said to feature an end-to-end production workflow including external cool down unpacking to maximise machine uptime allowing job-to-job turnover under one hour versus the days reported on competing technology.

In addition, the NXG platform features SLM Open Architecture allowing maximum flexibility to tailor process parameters to optimise application results with maximum productivity using 90 µm layer thickness and beyond in commonly qualified materials that can be processed including IN718, AlSi10Mg, TiAl6V4 & copper alloys. Support-free AM with Free Float capability offers maximum freedom in design, and reduces the need for both support structures and post-processing time by up to 90%. SLM.Quality performs efficient and robust quality assurance with documentation, process qualification, and part certification with the ability to generate a quality report in a reported two clicks, and fully document process data & validate part quality.

“We are pleased to continue our long-term partnership with SLM,” stated Edward J Sheehan, Jr, CTC president and CEO. “SLM is clearly a leader in the Additive Manufacturing equipment arena, and we look forward to collaborating and expanding the possibilities of Additive Manufacturing for defence applications in this exciting opportunity in support of critical AFRL mission requirements.”

Sam O’Leary, CEO for SLM Solutions, commented, “These are the partnerships that are a testament to SLM Solutions’ ethos; it is only in close collaboration with them that we can push the limits of innovation. To take a market leader like that of the NXG XII 600 as a blueprint, extend the envelope to 1.5 m, coupled with the precision and reliability of our systems, and our hands-on support allow our customer to develop with agility–almost at the Mach-speed that we are designing this system to build parts for. We are especially pleased to be teamed with CTC, a highly regarded premier research and development organisation with an outstanding record of securing technology transition successes.”