Sivó adds Meltio Engine for hybrid Additive Manufacturing

September 30, 2021

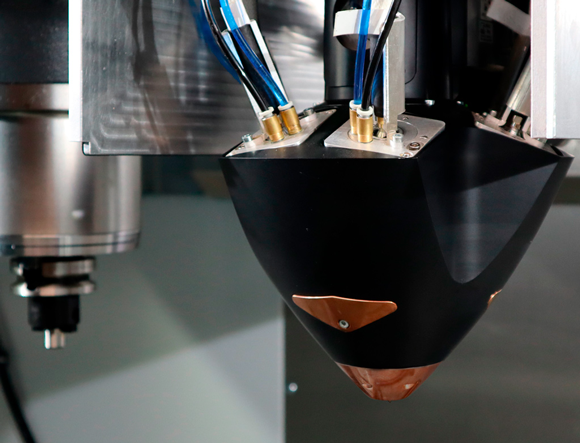

Meltio, Linares, Spain, reports that Sivó, an industrial machine shop based in Caudete, Spain, has installed the company’s wire-based Directed Energy Deposition (DED) technology in one of its CNC machines. With the support of Sicnova, Meltio’s official partner in the Iberian Peninsula, the Meltio Engine was added to a Haas UMC-1000SS CNC machine in just one week.

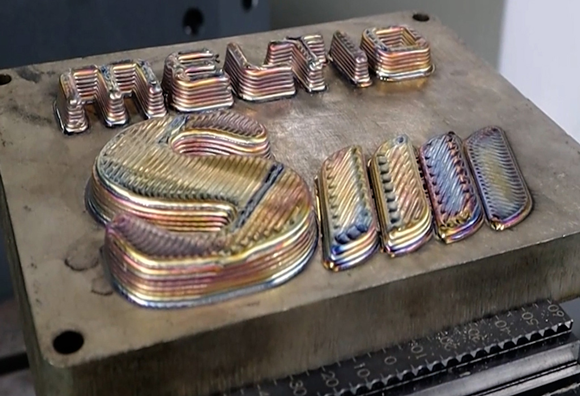

Sivó, the first company in Spain and Portugal to install the Meltio Engine hybrid Additive Manufacturing machine, will use the technology to improve its glass bottle mould repair process.

Meltio’s multi-metal AM technology uses basic welding wire, said to be the cleanest, safest and lowest-cost metal raw material on the market. The Meltio Engine integrates into existing robots and CNC machines, bringing new capabilities to a wide range of industries and applications.

The company explains that CNC integration maximises manufacturing potential by creating very complex large parts with machining tolerances in a single step. This, it says, provides countless advantages to machining workshops, such as Sivó.

“We are delighted to be working with Sivó and Sicnova, as collaboration between sales and integration partners within the Meltio ecosystem is critical to accelerating technology adoption in a territory. With Sivó’s expertise, we can now offer a comprehensive solution to customers who require hybrid manufacturing capability in Spain and Portugal,” stated Gerard García, Director of Marketing and Sales at Meltio.

Sivó has extensive experience in repair and adjustment of moulds of glass bottles and large valves, as well as models and prototypes. “Meltio’s technology allows us to finish a project started in 2016,” stated José Sivó Romero, Director of Additive Production at Sivó. “The objective is the improvement of the process and automation of the repair of moulds of glass bottles…This will allow us to expand the market for our products and improve our company on a technological level.”

Sicnova has been the exclusive distributor of Meltio technology in Spain and Portugal since 2019. The company is said to leverage its extensive experience in the industrial sector, and its well-established sales network, to introduce Meltio’s unique AM solutions to industries seeking a competitive advantage in their production process.

Agustín García, Commercial Director of Sicnova, stated, “Sivó plays a key role in our ecosystem, as the official Meltio Engine integrator for CNC equipment. At Sicnova, we firmly believe in the potential of this hybrid technology, which combines the best of subtractive technology with the additive manufacture of metals, for companies in the industrial sector that want to take a step further in its production processes, with special focus on machining, that is why we wanted to count on Sivó, with its extensive experience and know-how in this sector, so that our customers have all the facilities and our guarantee to implement this cutting-edge technology.”