Shukla Medical saves ‘$120,000 a year’ prototyping products on Markforged Metal X

October 12, 2019

Shukla Medical, St. Petersburg, Florida, USA, a surgical tool manufacturer and a subsidiary of aerospace manufacturer S.S. White Technologies, Milton Keynes, UK, has reportedly saved $120,000 each year since adopting a Metal X system from Markforged, Watertown, Massachusetts, USA, to additively manufacture prototypes for its surgical instruments.

Shukla Medical’s products are engineered for orthopaedic implant surgeons and are said to include ‘time saving’ features like quick connections and multiple extraction options to optimise surgical efficiency. The products must therefore to be prototyped and tested for form and fit by surgeons during the development stage, before the final parts are manufactured in high volumes.

Originally using CNC machining to manufacture its prototypes, Shukla Medical found that long lead times presented major delays in its iteration of prototypes, preventing the company from quickly getting its products to market. To counteract this, the company purchased a Markforged system in 2017 to additively manufacture prototypes out of carbon fibre.

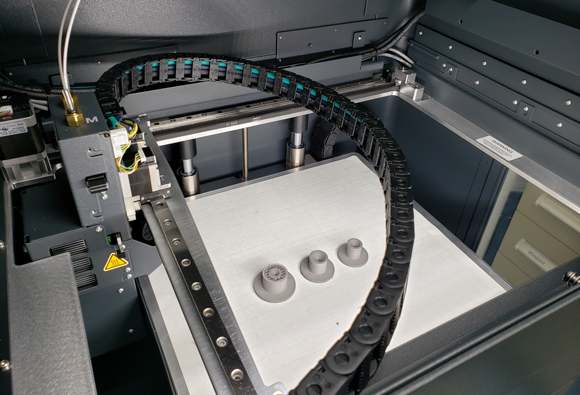

Following initial success with its carbon fibre AM system, the company invested in a Markforged Metal X system, said to have been chosen for its ease of use, wide range of materials, and the safety features. Because Shukla’s final surgical tools are produced in stainless steel, the ability to produce prototypes in the same material enables the team to conduct tests on the metal additively manufactured prototypes to verify and validate them, as well as allowing surgeons to practice with a tool as close to the final product as possible.

“The Metal X has let us print more complicated parts to conform to implant geometry that would have otherwise been very expensive to machine,” stated Adam Gosik-Wolfe, Mechanical Engineer at Shukla Medical. “I think we are at the tip of the iceberg with what we will be able to make with the Metal X in the coming years.”

Zack Sweitzer, Product Development Manager at Shukla Medical, commented, “We’re going to bring a lot more products to market faster with our Markforged printers, and we finally have the design freedom to do it.”