Shell moves towards digital inventory with additively manufactured impellers

May 13, 2022

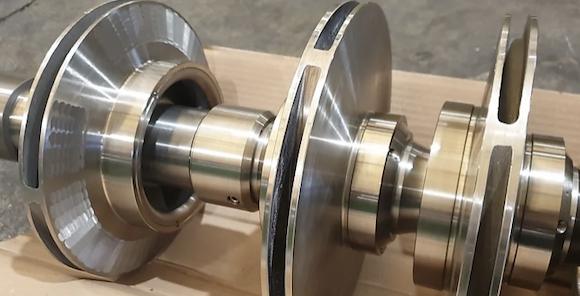

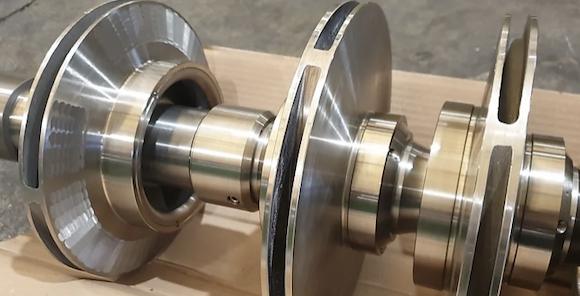

Global energy and petrochemical company Shell has announced the recent deployment of additively manufactured critical spare parts for a pump at the Shell Energy and Chemicals Park Rotterdam, the Netherlands. Working in collaboration with energy technology company Baker Hughes, the goal was to illustrate that additively manufactured impellers can safely and reliably meet the needs of critical pumps, removing the need to store these as costly spare parts.

Additive Manufacturing has been used at Shell over the last decade, but the criteria and testing to ensure the technical integrity of additively manufactured parts remains demanding. In 2019, Shell began to work with global suppliers to increase the portfolio of additively manufactured spare parts that can be supplied to the company. These cooperative relationships enable Shell to work together with suppliers to define the digital documentation of parts, and agree on what information is necessary to buy spare parts on demand rather than keeping parts in storage.

The company has worked with Baker Hughes to additively manufacture impellers for a medium-critical seven-stage centrifugal pump. The project showed that Additive Manufacturing can achieve the quality required for Shell’s operations and give confidence to the assets team that they don’t need to hold these items in stock, thereby saving a hundred thousand dollars for each stocked pump in operation. This is expected to open the door to significant, scalable savings for the company.

A key objective of this collaboration with Baker Hughes was to design a repeatable qualification process for vendors of additively manufactured parts, noted as crucial step to scale up the use of Additive Manufacturing in the energy sector. Shell qualified Baker Hughes facilities in Talamona, Italy, to supply its assets with additively manufactured spare parts. The two companies are working together to further create a digital portfolio of impellers that can be additively manufactured for Shell.

“This is an exciting development,” stated Leo van Driel, Senior Rotating Equipment Engineer, Shell Energy and Chemicals Park Rotterdam. “Shell and Baker Hughes’ 3D printing experts developed extensive research and quality verification steps. This helped convince us that additive manufacturing is a safe and reliable manufacturing technique for pump impellers. I feel that this may well be a game changer in spare parts management.”

The centrifugal pump was successfully started up with the additively manufactured components in May 2022. The pump has been subjected to intensive pre-installations testing to be accepted for operation and time will tell if, as the company anticipates, the new components will perform on par – if not better – than traditional impellers.

“Our journey with additive manufacturing started more than ten years ago in our laboratories, and today we use the technology in our manufacturing sites,” stated Enrico Mangialardo, General Manager, Baker Hughes Pump Division. “In collaboration with Shell, we are adopting innovative Additive Manufacturing solutions to reduce lead time and decrease physical inventories, while minimising the carbon footprint of operations. We believe it can significantly improve the way the supply chains work, including that of centrifugal pumps.”

Both teams stated they have learned a lot from mapping out the qualification requirements for the spare parts and in understanding the differences between companies in how they order parts and manage their supply chains. Embracing Additive Manufacturing will not only require technical expertise and building trust in the technology, but means companies must re-think internal processes and define new commercial models. The project is said to have proved that these are necessary steps to embrace a digital inventory strategy and ensure robust, secure and compliant exchanges of data for both parties.