Second stage of Skyrora XL rocket successfully static fire tested

August 18, 2022

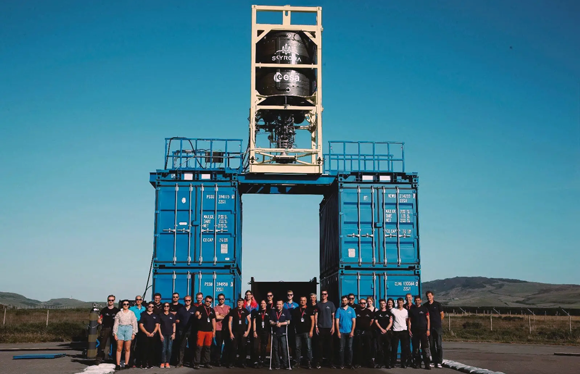

Skyrora, a rocket manufacturing company headquartered in Edinburgh, Scotland, which uses Additive Manufacturing for engine components, has successfully completed a static fire test of the second stage of its Skyrora XL orbital rocket at Discover Space UK, Machrihanish Airbase in Scotland. This brings Skyrora closer to achieving its goal of entering commercial operations, with an inaugural orbital launch scheduled for 2023 from the SaxaVord Space Centre in Scotland.

The Skyrora XL rocket was fully manufactured and assembled in-house including the assembly of the 70 kN engine produced using additively manufactured engine components. The company uses its own in-house Additive Manufacturing machine, the Skyprint 2, which uses the Directed Energy Deposition (DED) process to produce parts.

The static fire test involves hot firing the second stage engine to prove the vehicle’s operational capability for its intended payloads and ensure that its performance meets all the design requirements. Skyrora reports that the test was successfully completed with all systems nominal throughout the twenty-second burn, and the single 70 kN liquid engine operated within design margins and achieved the expected thrust.

“The static fire test looks, sounds and feels a lot like a rocket launch, but without lifting off! This hugely successful test was a definitive demonstration of our mobility and flexibility. Our Skyrora team went from clean tarmac to a full static fire test in just 2.5 days, bringing all the necessary equipment from our factory in Cumbernauld and test site near Gorebridge,” stated Lee Rosen, Skyrora COO Col (USAF, Ret) and former SpaceX VP.

Part of a three-stage launch vehicle, the second stage of Skyrora XL will start its engine at an altitude of approximately 62 km before the third stage is fired at around 190 km to achieve orbital velocity of 28,000 km/h. Skyrora tested the third stage of its XL launch vehicle in December 2020. The first stage of Skyrora XL is currently in construction, with hot fire tests due to take place in mid-2023.

Volodymyr Levykin, founder and CEO of Skyrora, commented, “With the UK striving to capture a 10% share of the global space market by 2030, the successful Skyrora XL second stage static fire test is the latest milestone reached to put Skyrora on track to become a key part of the UK’s new space industry as the first British company to conduct vertical launch from UK soil. Skyrora now has purpose-built rocket manufacturing and testing facilities in the UK – as well as the largest 3D printer of its kind, which we are using to produce rocket engine components. We recognise the value that a strong domestic space industry will bring to the UK, and we will continue to spearhead these efforts to make the UK a player to be reckoned with globally.”