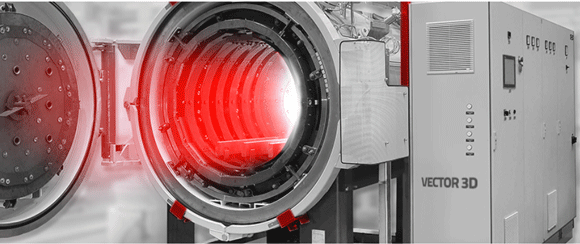

Seco/Warwick vacuum furnace for annealing AM components heads to aerospace manufacturer

June 23, 2020

Seco/Warwick Group, headquartered in Swiebodzin, Poland, reports it has sold a vacuum furnacefor the annealing of metal additively manufactured components to an international aerospace parts maker.

The order is for a single-chamber vacuum furnace from Seco/Warwick’s Vector® line. The Vector 3D model is said to combine all the advantages of gas quenching capabilities with the growing requirements of the Additive Manufacturing market.

In addition to annealing, the Vector 3D model allows customers to perform processes such as sintering, debinding, stress-relieving, ageing or solution heat treatment, which are essential for the metal AM sector.

“Seco/Warwick Group has delivered hundreds of Vector heat treat systems worldwide, many of which are in steady use supporting the aircraft industry,” stated Maciej Korecki, Vice President, Vacuum Business Segment at Seco/Warwick. “We offer Vector with either a horizontal or vertical chamber depending on part configuration and the process needs of the customer, and we support each customer all over the world with a dedicated team of aftermarket professionals to keep them running at peak efficiency.”