Safina and Präzi Group use various Additive Manufacturing processes for industrial surface hardening assembly

September 9, 2022

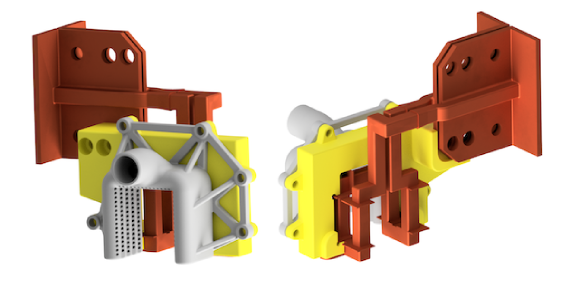

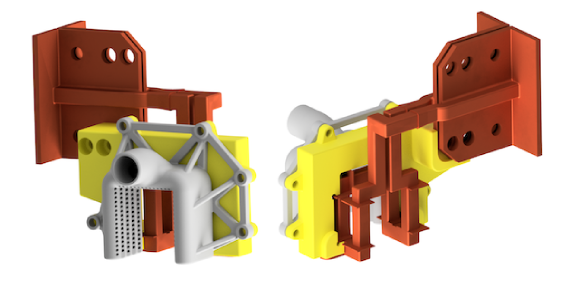

Safina, based in Vestec, Czech Republic, and the Czech branch of the German Präzi Group, based in Napajedla, are collaborating on a project that combines various additive manufacturing methods to produce an industrial assembly for surface hardening. Here, the team used both polymer and metal Additive Manufacturing processes to construct the individual parts, reducing lead times for the whole assembly and spare parts production.

The main part of the assembly is a copper surface hardening coil, where Laser Beam Powder Bed Fusion (PBF-LB) was used to additively manufacture pure atomised copper (4N). The coil would be split into two parts for manufacturability and project economics. Another important part of the assembly is the shower for cooling the hardened blank, where design optimisation was used to achieve lower weight. The original design was proposed for conventional fabrication using stainless steel welding; the new part was made from AlSi10Mg via PBF-LB Additive Manufacturing.

The primary aim of the project was to reduce the lead-time for the entire assembly of parts required for hardening the selected blank and to increase the lifetime of the induction coil or the entire assembly and thus any downtime. The secondary objective was to reduce the weight of the entire assembly so that assembly – and possibly service tasks – would be more convenient for the operator during installation and repair, as well as to reduce the power input for hardening.

Additively manufacturing copper and its alloys via PBF-LB is reported to be difficult due to its high reflectivity, which absorbs significantly less energy when exposed to the red laser common with other standard materials for PBF-LB. In order to achieve acceptable productivity and build quality, it is necessary to use a laser of a smaller wavelength (typically half of the red laser wavelength), such as the standard green (515 µm) or blue (less than 480 µm) lasers, with significantly lower reflectivity from the exposed layer.

In PBF-LB Additive Manufacturing machines with a smaller chamber (less than 150 µm in diameter), users may see the implementation of a green laser, where relatively good results are achieved when additively manufacturing pure copper. Implementation of the green laser in mid-size machines is likely to take a few more years, especially due to the characteristics of the standard 200/500 W green laser. Thus, a machine with a standard red laser, but with significantly higher power (here 1000 W), was used to additively manufacture the test prototypes for Safina and the Präzi Group.

The induction coil was positioned on the build platform in such a way as to ensure the absence of supports in the inner part of the geometry, while using just enough supports on the outer part to fix the coil and ensure optimum heat dissipation from the melted layer. The induction coil was designed to eliminate welds from the main part of the coil to increase its lifetime and reduce the power required to temper the selected blank.

The test results then showed that lead time was reduced by about 50% and that the coil showed at least 4X longer lifetimes than a conventionally manufactured piece. A reduction in the overall weight of the assembly by 60% was also achieved, and there was also a non-negligible reduction in the power required to quench the selected blank by about 10%. Thus, the companies have concluded that Additive Manufacturing has proven its effectiveness in surface hardening applications, not only on the inductors themselves, but also on other system components.