Safina adds copper alloy powders to AM portfolio

March 4, 2021

Safina, Vestec, Czech Republic, has recently added new gas atomised powders from ternary copper-based alloys to its portfolio, meeting the needs of high-end applications like the combustion chambers in rocket engines or heat sinks in nuclear fusion reactors.

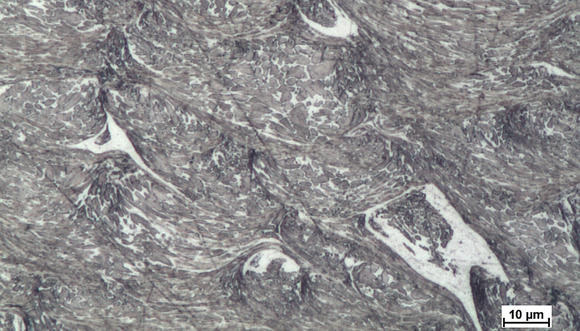

While pure copper has good thermal conductivity, its strength, especially at higher temperatures, falls short. With the introduction of some other elements like NB, Cr, Ag or Zr, there is an improvement in that strength while still preserving the high thermal conductivity at temperatures around 700ºK. Generally, Cr and Ag nano precipitates offer higher strength, while Zr acts as a grain refiner, blocking coalescences of nano precipitates, meaning precipitates have to be as small as possible to maintain high mechanical properties.

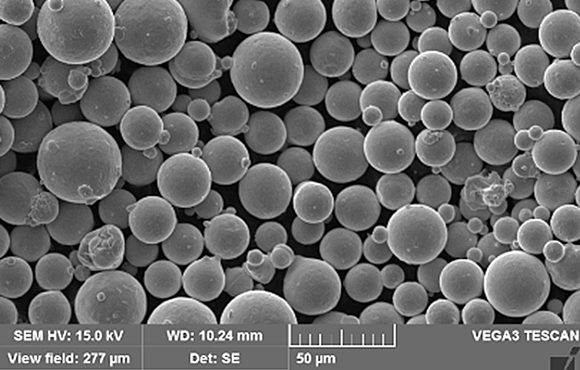

Alloys like CuCr1Zr are common, widely available as rolled semi-finished products (rods, plates and sheets). However, Safina found that it had to overcome several obstacles to produce higher quality powder, as the quality of raw material was found to be insufficient for AM production, either Laser Beam Powder Bed Fusion (PBF-LB) or Cold Spraying.

To ensure high, replicable quality of production powders, Safina developed its own high-purity master alloys, as even several tens of ppm impurities are detrimental and can cause Intermediate Temperature Embrittlement (ITE). The most important elements to watch are O2, H, Bi, Sn, Sb, Pb, Te, Se, P and Fe.

Safina has also altered the entire process, from melt atomisation to packing, in order to prevent oxygen contamination and reach optimal particle size distribution. This is especially important for its copper alloys, as copper powder is very sensitive to oxygen exposure and rapid oxidisation can influence its mechanical properties, meaning a proper handling procedure is vital at both sides of the supply chain.