Royal Air Force exploring Additive Manufacturing for aerospace parts

July 21, 2023

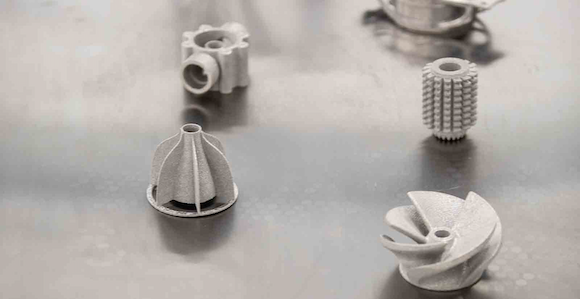

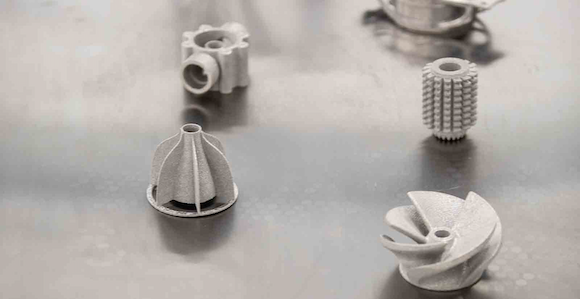

As reported in Aviation Week, the UK Royal Air Force is said to be experimenting with Additive Manufacturing in hopes to provide a way to produce urgently needed aerospace parts. Project Warhol, a team of four focused on Additive Manufacturing, has been funded by the Rapid Capabilities Office and the UK Defence Innovation Fund.

It is hoped that Additive Manufacturing could help reduce the reliance on contested logistics systems and make platforms more readily available when deployed overseas. Establishing Additive Manufacturing capabilities on the Royal Air Force’s bases would build on the capacity provided by station workshops performing precision metalwork.

Reportedly, the team hoped to have already flown its first in-house-produced part, a blanking plate, on an in-service Airbus Puma helicopter prior to the Royal International Air Tattoo. However, the component is undergoing a clearance process with military airworthiness authorities and is expected to fly shortly.

Chief Technician Mike Matthias, told Aviation Week, “This is not about producing main spars for combat aircraft, but creating components we can then ship to support forward assets.”

The team is believed to be developing its capability by using an Electron Beam Powder Bed Fusion (PBF-EB) machine for titanium, and a Laser Beam Powder Bed Fusion (PBF-LB) machine for aluminium parts. However, it is aware of the challenges in certification and intellectual property when producing alternative parts to those provided by OEMs. One possibility is to purchase the digital design files from the manufacturer for future iterations of the team, allowing production of the part as needed.

Project Warhol has reportedly been tasked with assessing the technology until March 2024, with the potential to extend the project. A final assessment is due by March 2025, at which point a decision will be made regarding AM’s capability within the RAF’s core budget.

Download Metal AM magazine